What is 3D printing technology for bottles?

With the continuous innovation of 3D printing technology, 3D printing technology has become more and more widely used among manufacturers, just like a new era of manufacturing mode.

Table of Contents

ToggleⅠ.What is 3D printing?

3D printing technology is a kind of surface printing technology realized by digital production mode, using computer technology and digital design. It can express the pattern and texture in more detail and precisely, to create a depth, layered 3D effect, making the printing pattern more realistic, three-dimensional, rich in texture. 3D printing technology is based on digital production methods, it is through the use of advanced computer software and hardware tools to design, optimize and produce the printing pattern, and the use of the three-dimensional geometric structure of the ink, through the use of machine parameters such as molding pressure, molding temperature, and generating models to position the ink to create multi-layered, multi-colored 3D patterns. Through multiple additions of pigment layers and fine vacuum adsorption technology, a highly three-dimensional printing effect can be achieved, making the appearance of products such as clothing, shoes, bags, and home furnishings more exquisite and realistic, satisfying consumer needs and aesthetic demands.

Ⅱ.Why choose 3D printing?

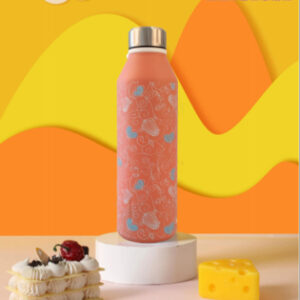

1.3D printing technology can create a more realistic, realistic effect. 3D printing technology can create a more realistic and 3D sense of pattern, making the appearance of the product more real and more attractive.

2. 3D printing technology can realize a large number of complex details. Compared with traditional printing technology, 3D printing technology can more easily and accurately create a large number of complex patterns and details. The technology is not limited by fixed templates, allowing for more design and innovation.

3. 3D printing technology is more economical and sustainable. Compared with traditional printing technology, 3D printing technology can save more materials and time, and can make it easier to meet personalized demands, so as to better cope with the growing competition in the market. In addition, the use of 3D printing technology can reduce waste and pollution, which can help achieve sustainable development.

4. 3D printing technology can provide personalized custom services, explore new markets and create new value. In the past, producers usually relied on traditional printing technology to produce large quantities of standardized products, while consumers could only pick their favorite styles from a limited selection of designs. But with the advent of 3D printing, producers can easily offer personalized, small-batch products through digital and customized production methods. 3D printing can provide a deeper level of customer satisfaction and open up entirely new markets. As a result, manufacturers can reap more opportunities and profits.

This advantage also brings the following benefits:

- Meeting different customer needs: 3D printing technology can ensure the production of personalized products that meet a variety of consumer requirements, including patterns, colors and styles. Consumers can make choices according to their needs and preferences and thus be more satisfied.

- Promoting product innovation: 3D printing technology makes it easier for producers to customize new products, which helps manufacturers create more innovative products that meet the needs of modern consumers.

- Establishing brand loyalty: With 3D printing technology, consumers can not only get more personalized products but also enjoy more personalized services from the brand, helping the brand to build and consolidate customer loyalty.

Ⅲ.What are the advantages of 3D printing compared to traditional surface processes?

In the traditional surface decoration field for water bottle manufacturing, processes like screen printing and laser engraving long held dominance. Among these, screen printing transfers patterns through ink leakage from a mesh screen, suitable for standardized mass production; laser engraving relies on high-energy beams to create indentations on the material surface, mostly used for single-color markings. However, as consumer market demand for personalized, high-quality appearance upgrades, the limitations of traditional processes in areas like 3D effects and customization flexibility are becoming increasingly apparent. 3D printing technology, as a digital surface decoration solution, breaks through the physical limitations of flat printing, bringing revolutionary changes to cup and bottle appearance design.

1. How is 3D printing applied to cup and bottle surfaces?

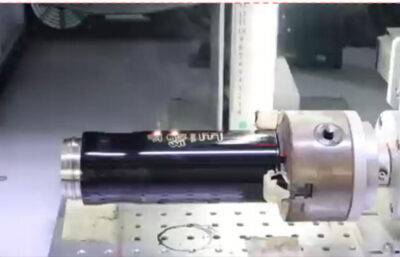

3D printing technology in the cup and bottle field is a digital printing technique focused on appearance decoration. Its core lies in designing three-dimensional patterns using computer software, utilizing special inks with geometric structures, and combining parameters like forming pressure and temperature to control ink positioning. This achieves multi-layer, multi-color textured printing on cup and bottle surfaces. Specifically, the technology is applied through the following paths:

-

Material and Process Compatibility: Selecting high-temperature resistant, corrosion-resistant inks compliant with food contact standards (e.g., specialized inks for 316L stainless steel or Tritan plastic). Using layered inkjet and vacuum adsorption technology, patterns with a raised texture, are formed on the curved surface of the cup body.

-

Digital Design Driven: Utilizing parametric design software, 2D patterns are converted into 3D models, directly generating printing paths. This enables the presentation of millimeter-precision textured patterns on cup and bottle surfaces without traditional mold-making processes, greatly enhancing design freedom.

2. How is screen printing applied to cup and bottle surfaces?

Screen printing on cup and bottle surfaces is based on the “ink leakage through screen mesh” principle. The specific process is as follows:

-

Screen Making: Creating stencil screens based on the design pattern. Ink is squeezed through the screen onto the cup/bottle surface to form a flat pattern. This process requires separate screens for different colors and patterns. Minimum order quantities per batch typically need to reach hundreds or thousands of pieces to amortize the mold cost.

-

Limitations Manifested: Only capable of flat printing, unable to present textured depth; color gradients rely on multi-screen registration, making complex gradients or multi-layered patterns difficult to reproduce; printing uniformity is poor on curved surfaces (like the arc of an insulated bottle), prone to ink pooling or missed printing.

Ⅲ. Comparison of Costs and Effects between the Two Processes

(1) Appearance Effect Comparison

(2) Durability Comparison

(3) Customization Flexibility Comparison

(4) Cost and Efficiency Comparison

In summary, 3D printing technology is becoming increasingly valuable in the marketplace for bottle manufacturing, providing efficient utility and personalized designs, as well as a more diverse range of colors and options to better meet consumer needs and compete for market share.