Looking for a reliable water bottle supplier?

If you have plans for:

- Private Label Bottles for Promotional Gifts

- Custom Logo Tumblers for E-commerce Brands

- Design a completely new bottle with a unique spout

- Bulk Production from Your CAD Designs

- Bring your sketch to life as a finished bottle

- Develop a smart water bottle with app control

- Partnering with a water bottle new supplier known for quality and capability

Receive catalog or reply in 24 hours!

What materials do we use for our water bottles?

- 18/8 food grade 304 stainless steel

- 316 stainless steel

- BPA-free Eastman Tritan

- Titanium

- Borosilicate Glass

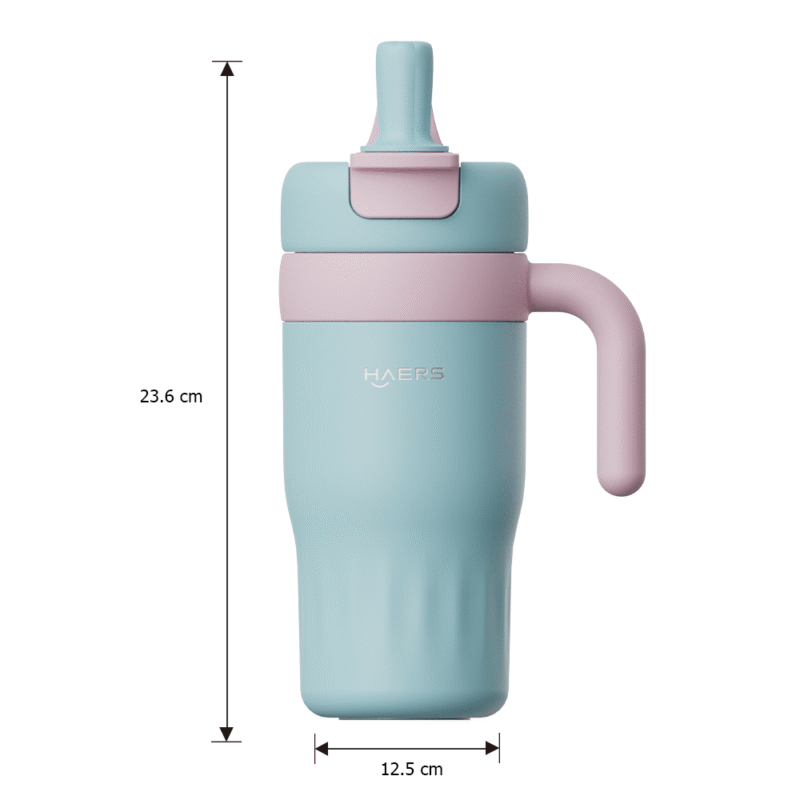

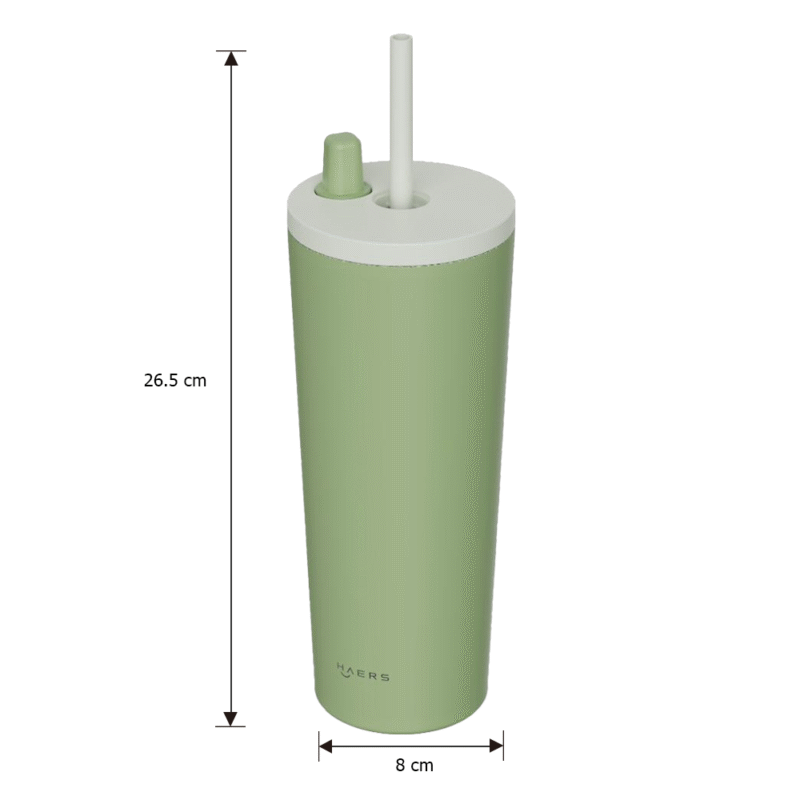

What types of vacuum containers can we produce?

- Insulated stainless water bottle

- Double-wall Tritan Plastic/ Glass water Bottle

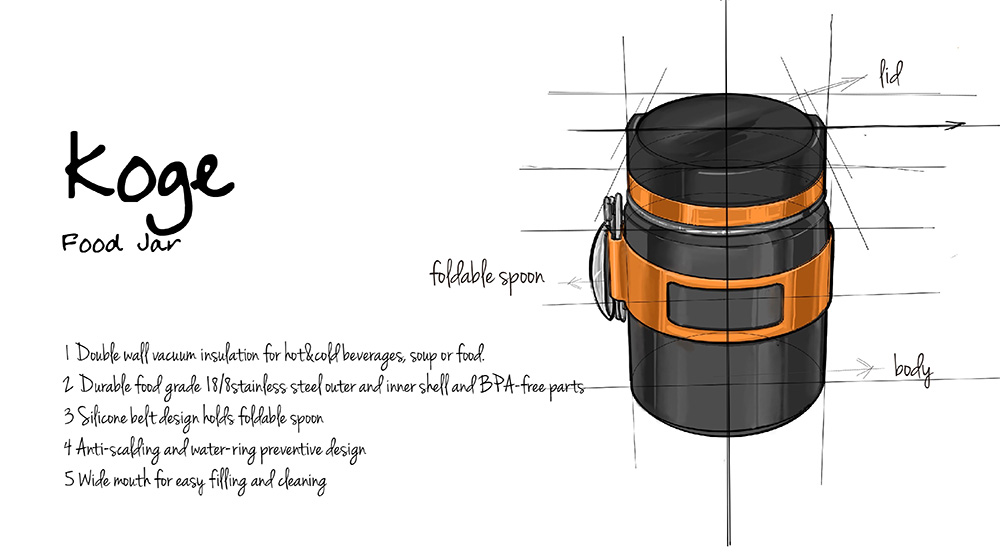

- Insulated lunch box/food jar

- App Controlled Smart Water Bottle

- Insulated Coffee Mugs

- Hydro Flask Kettle / Electric Kettle

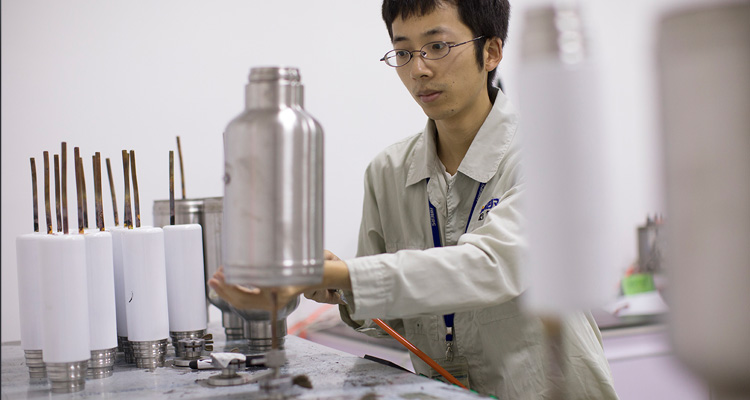

What We Do

Conception, Prototype, R&D, Molding, Scale Production, IP protection.... what we do is more than manufacturing

OEM

To deliver end-to-end solutions, we leverage our expertise in design, engineering, and manufacturing. Haers capabilities span from concept creation and industrial design to molding, production, driving rapid growth for your brands and businesses.

ODM

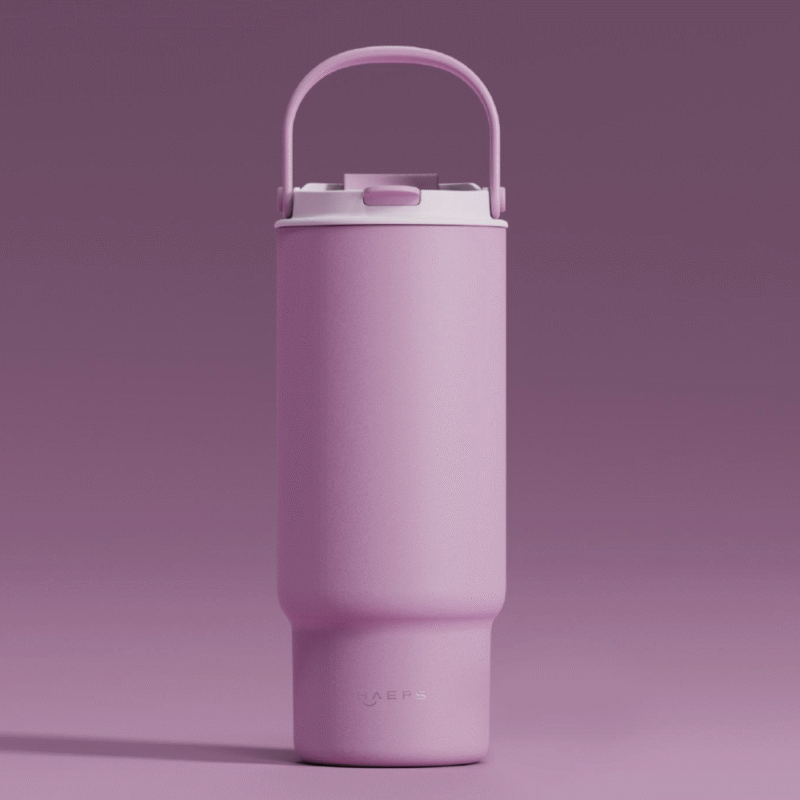

Annually, Haers launches over 120 competitive new thermos water bottles. Our diverse product line spans multiple materials and use cases, meeting a wide range of private label needs.

Smart Bottles

The R&D team has developed and patented smart chip technologies and proprietary components for smart water bottles, offering features like temperature display and control, hydration tracking, and health monitoring. Additionally, the app provides sleek, digital functions, meeting evolving market demands.

Bring concepts to life

If you’re looking to turn an idea into a bottle, our OEM service is the perfect solution for your brand.

Concepet Phase

Understanding user demands, drafting the first concept sketches, and revising designs are key steps in the concept design phase.

We collaborate with you to capture your initial product ideas and requirements, setting a strong foundation for the project.

Technical evaluation ensures your concept can be realized efficiently.

You and we together explore options and perfect the concept before finalizing the design stage.

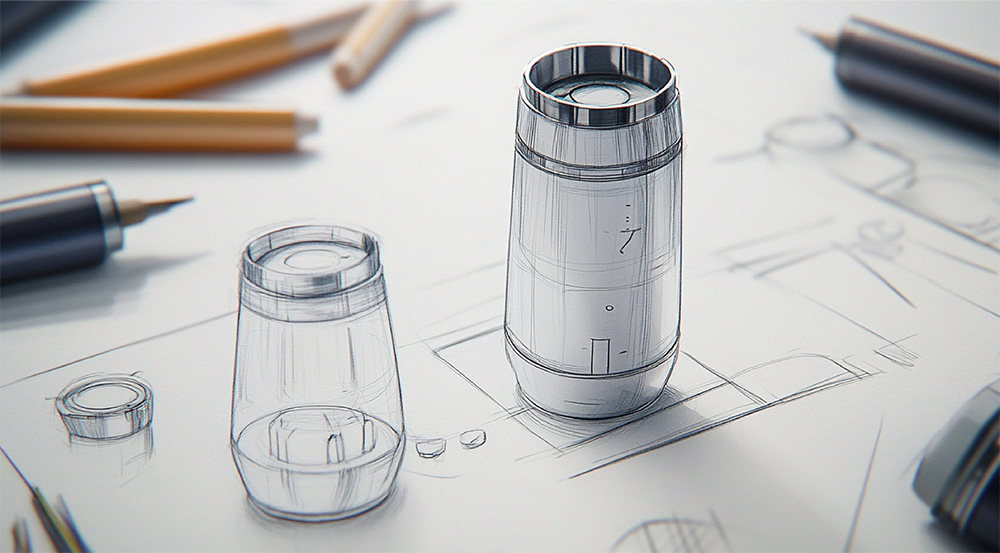

Sample Phase

In the sample stage, we finalize appearance, structure, prototype, and confirm the design for production readiness.

We create detailed 3D renderings and aesthetic designs for your review.

Structural design ensures the product’s durability, functionality, and user experience.

A high-fidelity prototype is built to verify design concepts.

Client feedback and confirmation mark readiness for mold development.

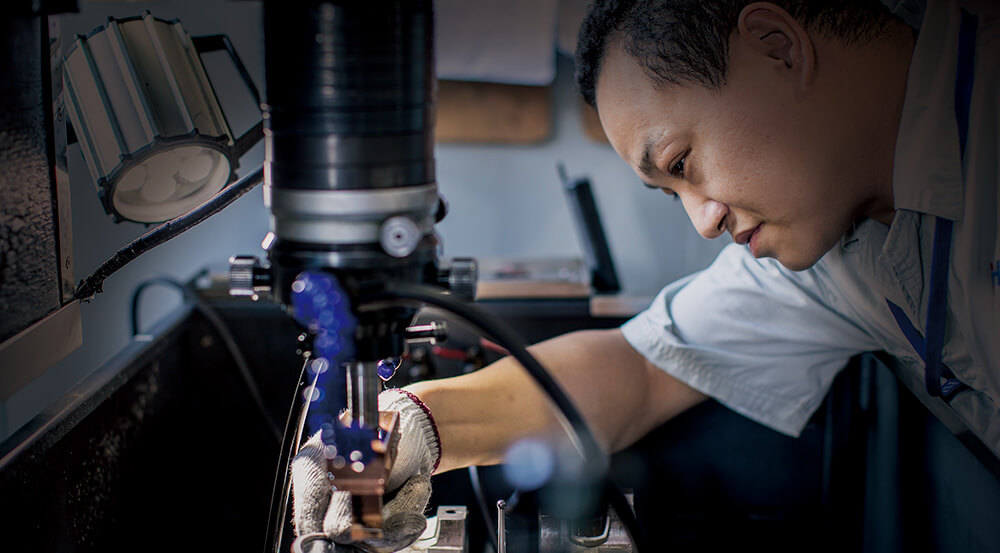

Trial Production

Coloring, tooling, sampling, and trial production are completed to confirm every detail before moving to full-scale manufacturing.

We develop the molds and perform precise color matching according to your specifications.

Sample production ensures molds, materials, and designs meet your standards.

We conduct a trial run to optimize the product and ensure smooth mass production.

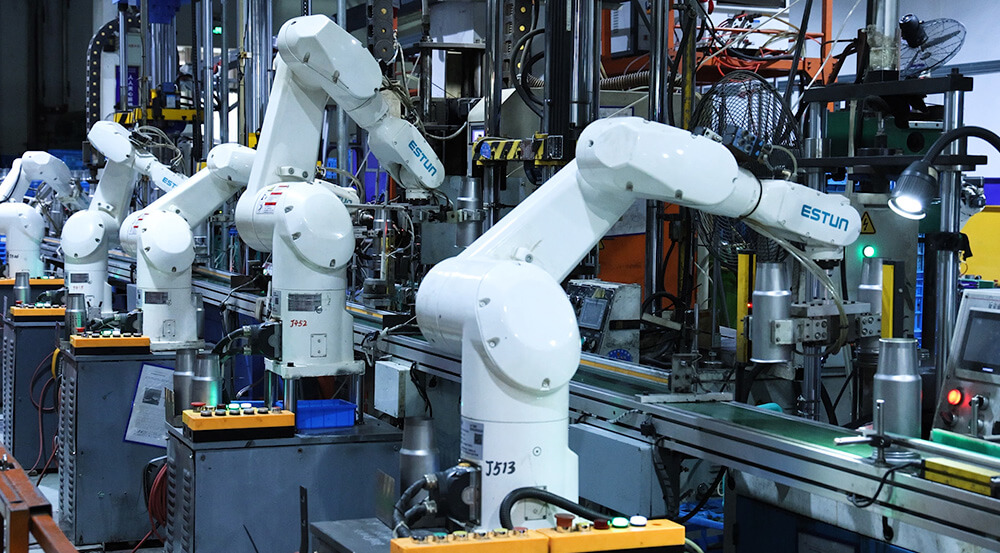

Scale Production

After completing 40 days of lab testing, we officially move into full-scale production to deliver consistent, high-quality products.

Products undergo comprehensive testing to meet international quality standards.

Upon final approval, we start large-scale production to deliver your custom products efficiently under Haers's quality control procedure.

Customize Water Bottle Surface

Haers provides more than 30 ways to paint the water bottle surface on stainless steel bottles, such as UV Ice Painting, Ceramic Painting, Anodic Oxidation, Ice Flower Painting, Rubber Painting and more.

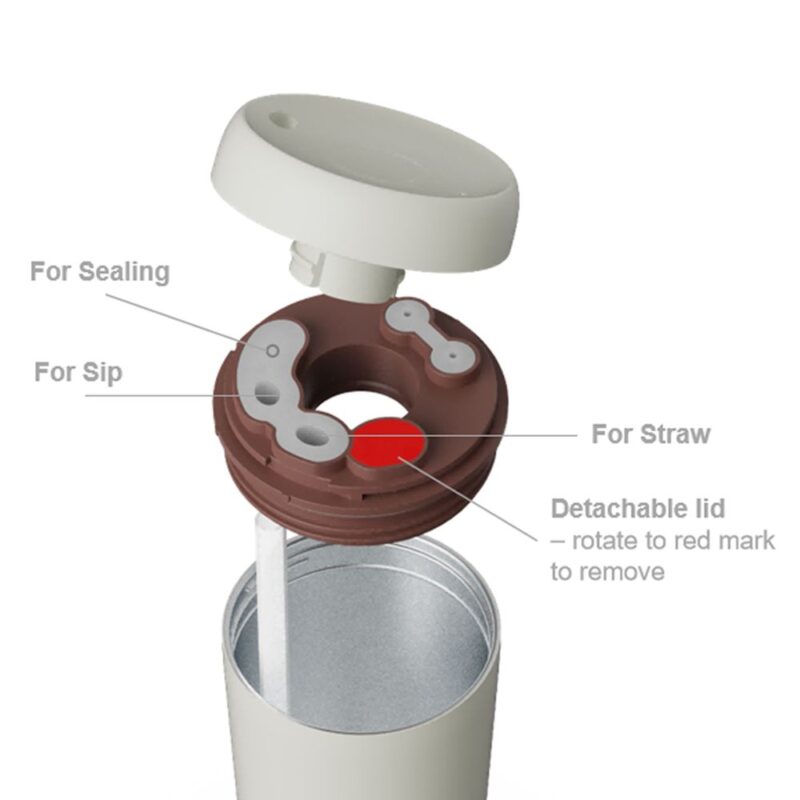

Custom Water Bottle Lid

You can choose from the lid designs already in our collection or work with Haers’ in-house molding workshop to design and create a custom lid.

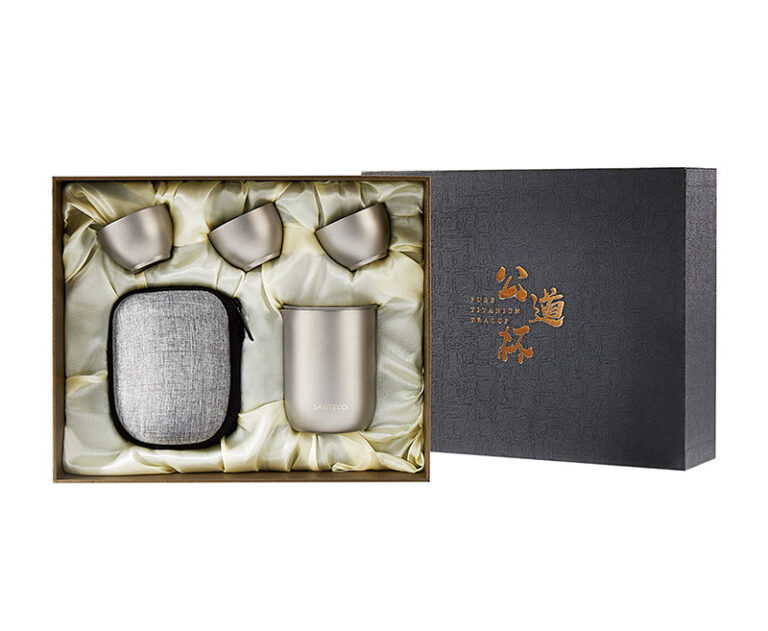

Custom Pacckaging

The packages are designed and assembled exactly to your specifications, ensuring a personalized and tailored solution to meet your needs. Whether it’s individual product boxes, multi-piece sets, PDQ displays, gift boxes, or even cotton drawstring bags paired with single-item packaging, we can tailor the design to your preferences.

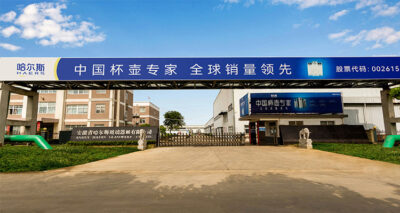

Stable Production Capacity

Haers owns five manufacturing bases located in Yongkang(China), Lin'an(China), Anhui(China), Thailand and Switzerland, forming a global manufacturing powerhouse. Nearly $300 million was recently invested in two new manufacturing bases in Thailand and Yongkang, making Haers the largest manufacturer of stainless steel thermos water bottles and flasks in the world.

290,000

square meters of factories

800,000

units produced per day

350+

R & D engineers

5

factory bases

Yongkang,

China

Specializes in the production of stainless steel thermos

Linan,

China

Produce stainless steel, Tritan water bottles

Amata,

Thailand

Produce stainless steel insulated tumbler

Anhui,

China

Focuses on glassware R&D and production

Your Reliable Stainless Steel Water Bottle Supplier

Top-rated quality control

Each production line undergoes multiple inspections to identify any abnormalities, ensuring the utmost quality in every piece.

Five Factories around the Globe

Haers owns five factories in China, Thailand, Switzerland, and a new intelligent lighthouse base is under construction.

With most awards and certifications

Haers has earned over 50 international certifications and more than 200 domestic certifications, 684 valid patents.

High-level In-house Lab

Haers has a comprehensive product testing process and the necessary equipment, with its testing capabilities reached at a national level.

Striving toward carbon neutrality

By enhancing production techniques and adopting energy-efficient equipment along with solar power, Haers is committed to achieving carbon neutrality.

Protection Your intellectual property

We emphasize the importance of intellectual property rights, making us the only enterprise in the industry with a customer IP protection system.

FAQ

Questions and answers about customization options, orders and production, quality and certification

Absolutely, we provide branding services for your brand.

We offer laser marking, silk screen printing, 4D printing, heat transfer, and air transfer, among others. Please consult our R&D team for more details.

Yes, please contact us, and we will send you an electronic version of the Pantone color chart for you to choose from.

Yes, the largest OEM clients in the industry have been working with us for over ten years.

We have many stock styles available, which are convenient for customers who want to test in small quantities. Please don't worry and consult us; we will send you the materials for verification.

The lead time for customized bulk production is usually around 45 days.

Yes. However, we recommend referencing existing samples for quality and style. The lead time for custom samples is around 20 days.

Existing samples cost $50, and custom samples are priced based on specific requirements, averaging $100.

We usually offer discounts in the form of tiered pricing.

All our products can pass food-grade tests. If you have specific local testing requirements, we will support and cooperate with you to conduct these tests.

Stainless steel materials are rust-resistant, but if you have high anti-corrosion requirements, we can produce with 316 interior walls.

e have the most complete and mature quality control system in the industry. We can jointly customize the standards you need.

Yes, please contact us, and we will send you the reports.

FDA, LFGB, Reach, and others can all be passed. However, new models or custom designs require new tests. We guarantee that our products will pass these tests.

We welcome discussions on handling quality issues at the beginning of our cooperation. Each brand has different quality requirements and after-sales terms.

Would like to knore more?

Whether you're looking for private label bottles or want to create a completely new water bottle, Haers has the capability to help you achieve your goals.