Why the Same Vacuum Technology Delivers Different Insulation Times

Have you ever noticed that while almost every insulated bottle on the market uses vacuum technology, some of them can keep your coffee hot for more than 24 hours, while others struggle to last even 10?

It sounds puzzling, right? If they’re all “vacuum insulated,” shouldn’t the performance be about the same? Well, not quite. Just like two chefs can use the same recipe but produce completely different dishes, the way vacuum technology is applied—and the little design details around it—can make a world of difference in how long your drink stays hot (or cold).

In this article, we’ll uncover the secret behind vacuum insulation, explore why some insulated bottles outperform others, and reveal the extra tricks insulated drinkware manufacturers use to push thermal performance to the next level.

Table of Contents

ToggleThe Basics of Vacuum Insulation Technology

What Is Vacuum Insulation? At its core, vacuum insulation is surprisingly simple: take two layers of stainless steel, suck the air out from in between, and seal it shut. That empty space—the vacuum—is what makes the magic happen.

Without air in the middle, there’s nothing to carry heat from one wall to the other. It’s like building an invisible barrier around your drink, keeping hot drinks hot and cold drinks cold for hours.

To really understand why vacuum insulation works so well, let’s look at the three ways heat normally escapes—and how the vacuum shuts each one down:

- Conduction – Normally, heat spreads as molecules bump into each other, like a chain reaction. With almost no molecules in the vacuum gap, there’s nothing to pass the heat along.

- Convection – In open air, warm air rises and cool air falls, creating circulation that moves heat around. But in a vacuum? No air, no circulation, no convection.

- Radiation – Heat can still try to sneak out in the form of infrared energy. That’s why many bottles use a reflective coating—like copper plating or a special metallic layer on the inner wall—to bounce this energy back and reduce heat loss.

Put together, this triple defense system explains why vacuum technology is the gold standard for keeping drinks at just the right temperature.

Key Factors That Affect Vacuum Insulation Performance

Vacuum technology may sound straightforward, but not every insulated bottle is built the same way. Several design and manufacturing details can make a huge difference in how long your drink actually stays hot or cold. Let’s break down the key factors:

1. Stainless Steel Material

Not all steel is created equal. High-quality 304 or 316 food-grade stainless steel is the gold standard in drinkware. These materials resist rust, prevent metallic taste, and stand up to daily wear and tear. Cheaper alloys may look similar at first glance, but they compromise durability and insulation performance over time.

2. Vacuum Sealing Process

The “vacuum” part of a vacuum insulated tumbler depends on precise engineering. A poorly executed sealing process allows tiny leaks of air to creep in, which drastically reduces insulation time. High-precision vacuum sealing technology ensures the gap stays airtight, keeping the insulation stable for years.

3. Inner Wall Treatment

Some premium bottles go the extra mile by adding a copper coating or other reflective layers like aluminum foil on the inner wall. This extra step minimizes heat radiation, giving you noticeably longer temperature retention. Think of it like adding an extra mirror to bounce heat back into your drink.

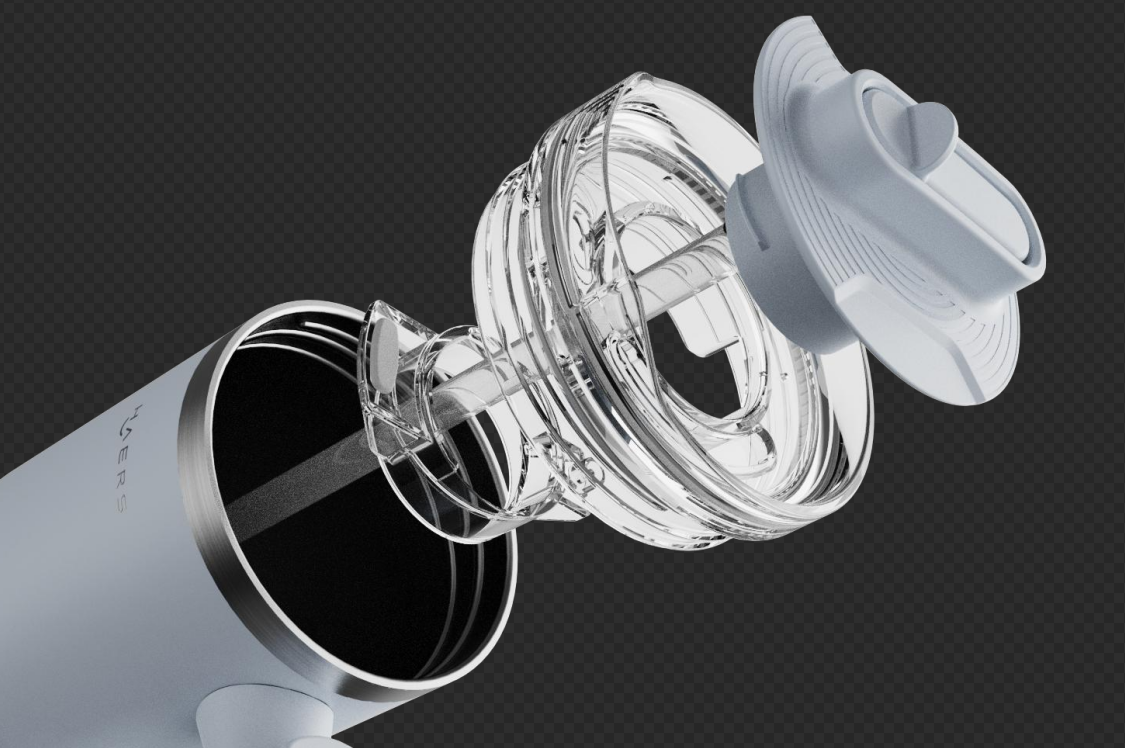

4. Lid Design and Seal

Even the most advanced vacuum chamber won’t save you if the lid leaks. A well-designed lid, paired with food-grade silicone gaskets, prevents heat (or cold) from escaping through the top. The lid’s structure and materials are just as important as the bottle body when it comes to real-world performance.

Together, these factors explain why two bottles that both claim to use vacuum technology can perform very differently in practice.

Advanced Techniques to Enhance Insulation Performance

While basic vacuum insulation provides good heat retention, manufacturers often adopt additional methods to push performance even further. These techniques are commonly found in premium tumblers and bottles, where longer heat preservation is a key selling point.

1. Copper Plating on Inner Wall

Applying a copper coating inside the vacuum chamber creates a highly efficient reflective layer. This layer significantly reduces thermal radiation, ensuring that heat stays inside for hot beverages and outside for cold ones.

2. Aluminum Foil Reflective Layer

Some designs use aluminum foil or specialized metallic coatings as an extra barrier. This reflective layer works like a mirror for heat, bouncing it back and preventing temperature loss through radiation.

3. Multi-Layer Structure Design

In high-end products, manufacturers add extra insulation layers beyond the vacuum chamber. These may include foam layers, ceramic coatings, or double-reflective films. The additional structure helps extend the insulation time and improves user experience in extreme conditions.

4. Vacuum Enhancement Process

To keep the vacuum stable over years of use, advanced processes such as high-vacuum pumping combined with laser welding are applied. This ensures the chamber is thoroughly sealed and maintains its insulating performance much longer compared to standard manufacturing methods.

Common Use Scenarios for Insulated Bottles

Vacuum insulated bottles are not just a technical innovation — they have become part of people’s daily routines across different lifestyles. Let’s look at some of the most common scenarios where users prefer them, and why.

1. Office and Daily Work

For many office workers, having a hot cup of coffee or tea available throughout the day is a small comfort that boosts productivity. A reliable vacuum bottle keeps drinks warm during long meetings or while working at the desk.

2. Outdoor Activities and Travel

Whether it’s hiking, camping, or long-distance road trips, vacuum bottles are essential. They ensure hot soup stays steaming in cold weather, or iced water stays refreshing during summer adventures. Portability and durability make them a favorite for travelers.

3. Fitness and Sports

Athletes and fitness enthusiasts often bring insulated bottles to the gym or the field. Cold water after intense training is refreshing, while warm drinks can be comforting after outdoor winter workouts.

4. Commuting and On-the-Go Lifestyles

For people who spend hours commuting, insulated tumblers or travel mugs keep morning coffee hot until they arrive at work. It’s not only convenient but also helps reduce reliance on disposable cups.

5. Parenting and Family Care

Parents often use vacuum bottles to store warm water for preparing baby formula, or to keep drinks at the right temperature for children during outings. The safety and reliability of insulation are especially valued in this scenario.

6. Seasonal and Extreme Conditions

In cold winters, a hot drink can be a lifesaver during outdoor work or long commutes. In scorching summers, a bottle that keeps water ice-cold provides comfort and hydration. This seasonal demand makes insulated bottles an all-year-round necessity.

Many leading retail brands in the insulated bottle homeware, such as Thermos, Hydro Flask, YETI, and more, have set the high standard for heat retention. Their success is not accidental — they employ top-tier manufacturing techniques, including precision vacuum sealing, copper or reflective inner coatings, high-quality stainless steel, and carefully engineered lid designs. These brands demonstrate that superior insulation is a combination of material selection, advanced processes, and rigorous quality control.

For B2B buyers, a practical way to understand performance differences is to explore the market directly: purchase bottles from various brands and price ranges in supermarkets or online, and compare their insulation capabilities. This hands-on research can reveal the subtle but critical factors that affect heat retention.

As China’s largest OEM manufacturer of stainless steel insulated bottles, Haers is uniquely positioned to provide customized solutions that go beyond standard vacuum technology. Our advanced insulation systems integrate multiple enhancements, ensuring longer heat retention, improved durability, and consistent performance tailored for your brand.

If you are looking for a reliable partner to supply high-performance, customizable insulated stainless steel water bottles, contact Haers today to discuss your wholesale and ODM/OEM projects.