What is laser engraving?

Table of Contents

ToggleI. What is laser engraving?

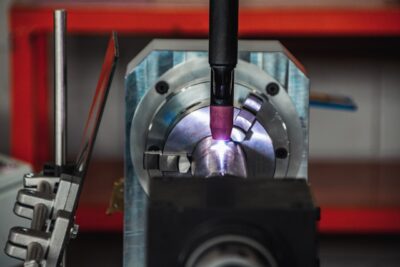

Laser engraving is one of the most widely used applications of laser processing. It involves marking a material by using a high-energy laser beam to locally irradiate its surface. This causes the surface material to either vaporize or undergo a chemical reaction that changes its color, leaving behind a permanent mark.

The core principle of laser engraving is based on a laser generator producing a high-energy, continuous laser beam. This focused beam is directed onto the material’s surface, causing it to melt or vaporize instantly. By precisely controlling the laser’s path, intricate graphics or text can be engraved onto the material.

The focused laser beam acts like a fine tool that removes material point by point. A key advantage of this process is its non-contact nature, which eliminates mechanical stress or damage to the material. The laser’s small focal point ensures a minimal heat-affected zone, enabling highly detailed and precise engraving that is unattainable through conventional methods.

II. Advantages of Laser Marking

- Non-Contact Processing

Laser marking does not involve physical contact with the workpiece, avoiding mechanical force or cutting pressure. This ensures the original accuracy of the material, minimizes heat-affected zones, and reduces the risk of deformation. The process is highly adaptable to various materials and can produce fine, durable marks on surfaces. - Flexibility and Precision

Laser technology offers excellent spatial and temporal control, making it versatile for different materials, shapes, sizes, and processing environments. It is particularly suitable for automated and specialized surface processing. The method supports both unique, small-scale designs for prototyping and large-scale industrial production with consistent quality. - Anti-Counterfeiting Features

Laser marking creates highly detailed marks, with line precision ranging from millimeters to microns. These marks are difficult to counterfeit or alter, making laser technology an effective tool for product authentication and anti-counterfeiting. - Automation and Efficiency

Combining laser marking systems with computer numerical control (CNC) technology enables efficient automation. This allows for engraving various texts, symbols, and patterns, while software tools make it easy to modify designs and update markings. Laser marking meets the demands of modern, fast-paced, high-efficiency production environments. - Environmentally Friendly Technology

Unlike traditional methods such as screen printing, laser marking produces no pollutants—there are no emissions, wastewater, or waste residues. This makes it a clean, sustainable, and environmentally responsible processing technology.

In the water bottle industry, where appearance and quality significantly influence consumer preferences, laser marking stands out as a high-precision, efficient, and non-polluting technology. It supports customization and personalization, enabling manufacturers to differentiate their products and improve market competitiveness.

Additionally, laser engraving reduces production costs and energy consumption, aligning with the principles of sustainable development. Its ability to deliver environmentally friendly and high-quality results makes it an increasingly essential tool for water bottle manufacturers aiming to meet evolving consumer demands and market trends. As laser engraving continues to advance, its applications in the bottle industry will expand, offering manufacturers greater opportunities for innovation and growth.