The second water bottle factory in Thailand was put into use!

We are pleased to announce that the second phase of Haers’ water bottle factory in Thailand has officially been put into operation. This expansion marks a significant milestone in our global manufacturing strategy, enhancing our “Made in Thailand” capacity to better serve international clients with efficient, high-quality production.

Table of Contents

ToggleWhere is Haers Thailand water bottle factory

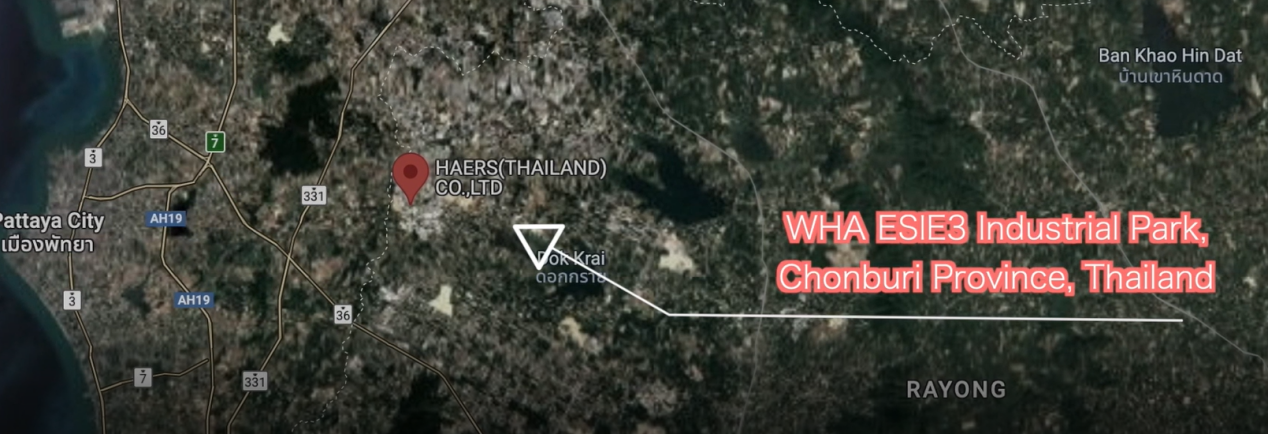

The second phase of Haers’ Thailand factory covers a total construction area of approximately 74,650 square meters and is located in the WHA ESE 3 Industrial Estate in Chonburi Province—an area widely recognized as a strategic “golden location.” The site is just 40 kilometers from Laem Chabang Port, a 45-minute drive, and approximately 110 kilometers, or 90 minutes by car, from Bangkok International Airport. This location offers a significant logistical advantage, accelerating transportation efficiency and ensuring smoother, faster movement of bottles.

What’s the production capacity of the second Thailand factory?

In terms of production capacity, the second Haers Thailand factory is equally impressive. The production area will consist of two main workshops and is planned to employ over 3,000 employees. Once fully operational, the factory is expected to achieve an annual output of 40 million units.

A dedicated workshop within the facility is equipped with 6 automated metal processing lines, 3 copper plating lines, 9 lead-free vacuum machines, 3 fluorine-free coating lines, and 3 packaging lines—enabling a projected annual production of 15 million units. All production lines are fully integrated with Haers’ advanced digital systems, forming a sophisticated and efficient manufacturing matrix. This high level of automation ensures a stable, timely supply for large-scale peak season orders as well as flexible production for customized, niche-market demands.

The second factory can manufacture a diverse range of stainless steel water bottles. The automated metal lines support the production of everything from minimalist daily-use bottles to high-end thermal tumblers tailored for various scenarios—from work to leisure to outdoor adventures. The fluorine-free coating lines deliver colorful, eco-friendly finishes that meet consumer preferences for both aesthetics and safety. Meanwhile, the lead-free vacuum technology enhances insulation performance while ensuring product safety and user comfort.

Made in Thailand, Built to Haers Standards

The second Haers Thailand factory represents more than just an expansion in capacity—it is a comprehensive upgrade in quality control, supply chain efficiency, and sustainable manufacturing.

Quality Control

To ensure consistent product excellence, the factory has implemented an upgraded quality management system aligned with Haers’ domestic standards. Equipped with advanced automation, the facility uses precise technologies such as automatic key dimension detection and infrared temperature monitoring to maintain tight tolerances during production. An independent testing center conducts rigorous performance and IP protection assessments, guaranteeing that every product meets the highest standards before delivery.

Local supply chain

On the supply chain front, Haers has made significant progress in local sourcing. The factory now works closely with regional suppliers for recycled stainless steel, powder coatings, silicone components, packaging materials, and injection molds. This localized procurement approach shortens the supply chain, reduces costs, and enhances resilience—allowing for faster market response and more competitive pricing, while also supporting local economic development.

Commitment to sustainability

Sustainability is a core pillar of the new facility. The factory is installing 8,995 solar panels, expected to generate 7.425 million kWh of clean energy annually, reducing carbon emissions by over 3,267 tons. This investment not only aligns with global environmental standards but also enables Haers’ partners to offer products with a clear sustainability value—meeting growing consumer demand for eco-friendly goods and enhancing brand image through responsible manufacturing.

How brands benefit from Haers Thailand factory

With the second factory in Thailand now fully operational, Haers is not only expanding its manufacturing capabilities, but also delivering additional value to brand retailers worldwide.

Convenient shipping and Thailand’s tariff policies

Haers’ second factory in Thailand enables direct shipping from nearby ports, with Laem Chabang Port only 40 kilometers away—just a 45-minute drive. This strategic location offers significant logistical convenience for brand retailers.

Moreover, by leveraging Thailand’s favorable export tariffs to the U.S. and other countries, brands can mitigate the uncertainties caused by fluctuating global trade policies. This helps reduce overall costs, allowing retailers to allocate more resources to product development, marketing, and customer engagement. Lower costs not only enhance price competitiveness but also provide more flexibility in market strategies—whether it’s leveraging price advantage or adding value to premium products.

This combination of shipping efficiency and tariff benefits gives brand retailers a strong foundation to navigate dynamic market environments with confidence.

2. The unique appeal of “Made in Thailand”

Against the backdrop of growing trade restrictions in certain regions, Thailand has maintained robust trade relationships with numerous countries, making it a strategic manufacturing hub. Products labeled “Made in Thailand” often benefit from preferential trade agreements, facilitating smoother access to a wider range of global markets. This label acts like a universal key, opening doors to international opportunities.

Beyond trade advantages, “Made in Thailand” also adds a unique marketing value. In some markets, consumers associate Thailand-made products with quality craftsmanship and cultural appeal, which can enhance product perception and boost sales. Additionally, Thailand offers a favorable investment environment, competitive labor costs, and continuously improving infrastructure. These factors contribute to lower operational expenses, greater pricing flexibility, and stable production. As a result, “Made in Thailand” is not just a country-of-origin label—it’s a strategic asset for enhancing product competitiveness and expanding market reach.

Faster logistics

Thailand’s central location in Southeast Asia positions it as a vital logistics hub. With its modern port infrastructure and extensive connectivity, Haers’ Thailand factory allows products to quickly reach both regional and global markets. This translates into shorter delivery times and reduced shipping costs—advantages that empower brands to respond more swiftly to consumer demand.

For example, shipments from Thailand to regions like Australia and South Asia can now be delivered much faster, giving retailers a valuable edge. In today’s fast-paced market, speed is critical. Faster logistics mean quicker product launches, enabling brands to capture attention early and meet consumer expectations for freshness and immediacy. It also helps reduce inventory turnover cycles and associated costs. With Haers’ optimized supply chain, retailers can minimize delays, stay ahead of trends, and enhance customer satisfaction—all while securing a first-mover advantage in competitive markets.

A look back at Haers first Thailand factory

Haers (Thailand) Co., Ltd. was established in 2022 as a wholly owned subsidiary of Zhejiang Haers Vacuum Containers Co., Ltd., with the primary mission of supporting overseas orders. In 2024, the first phase of Haers’ Thailand factory was officially completed and put into operation, with a designed production capacity of 5.5 million units per year.

Located in the Thai-Chinese Rayong Industrial Zone, the factory benefits from excellent transportation infrastructure. It sits just 128 kilometers from the airport and only 40 kilometers from Laem Chabang Port, offering seamless connectivity and highly efficient sea freight logistics.

The establishment of the second factory builds upon the success of the first. With production beginning in 2025, the second facility continues Haers’ commitment to delivering high-quality “Made in Thailand” drinkware to our global customers. Together, the two factories form a strong manufacturing base in Thailand, supporting international growth with reliable capacity and trusted Haers quality.