Bring concepts to life

With 300+ designers and engineers to bring ideas to life, and ensure quality at every step.

Bottle Manufacturing from Ideas

If you’re looking to turn an idea into a bottle, our OEM service is the perfect solution for your brand.

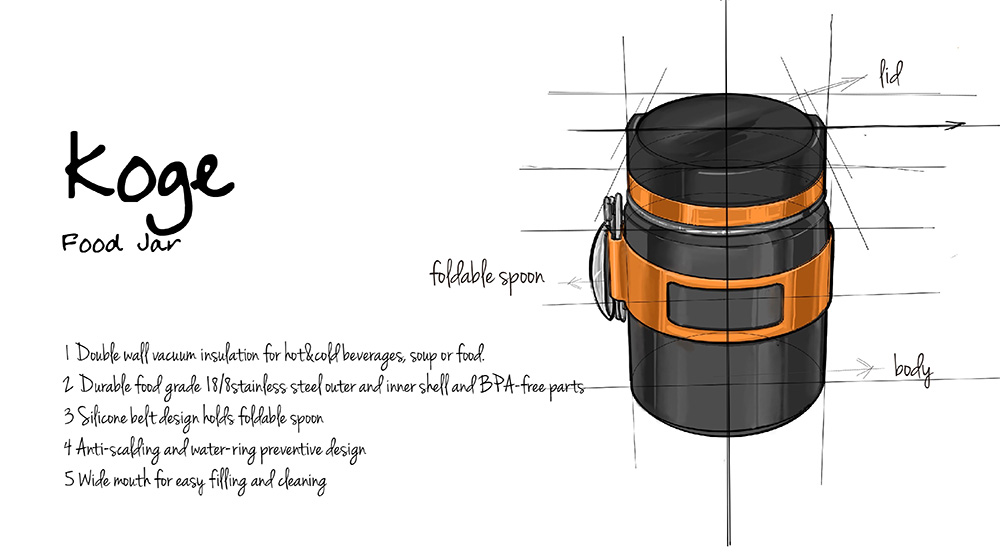

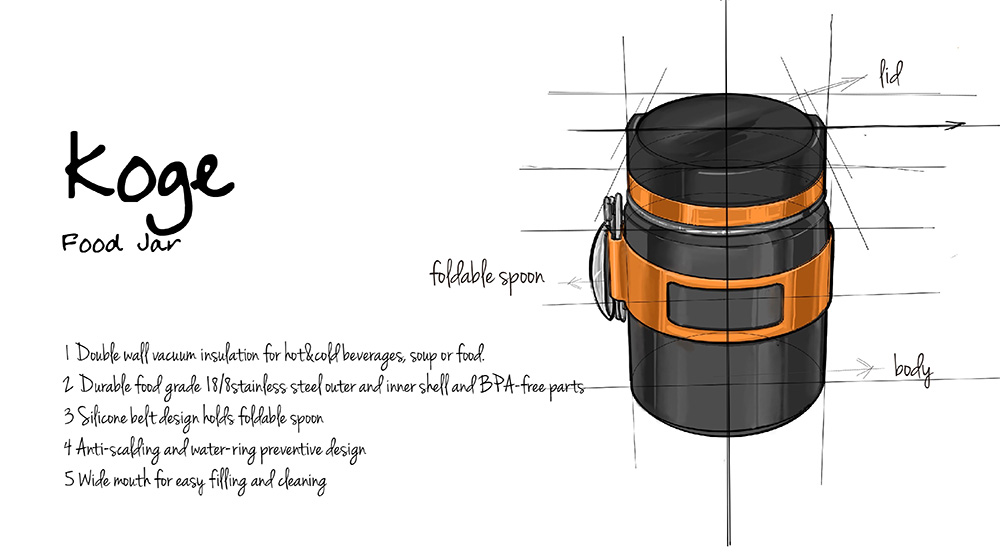

1. Concepet Phase

Understanding user demands, drafting the first concept sketches, and revising designs are key steps in the concept design phase.

We collaborate with you to capture your initial product ideas and requirements, setting a strong foundation for the project.

Technical evaluation ensures your concept can be realized efficiently.

You and we together explore options and perfect the concept before finalizing the design stage.

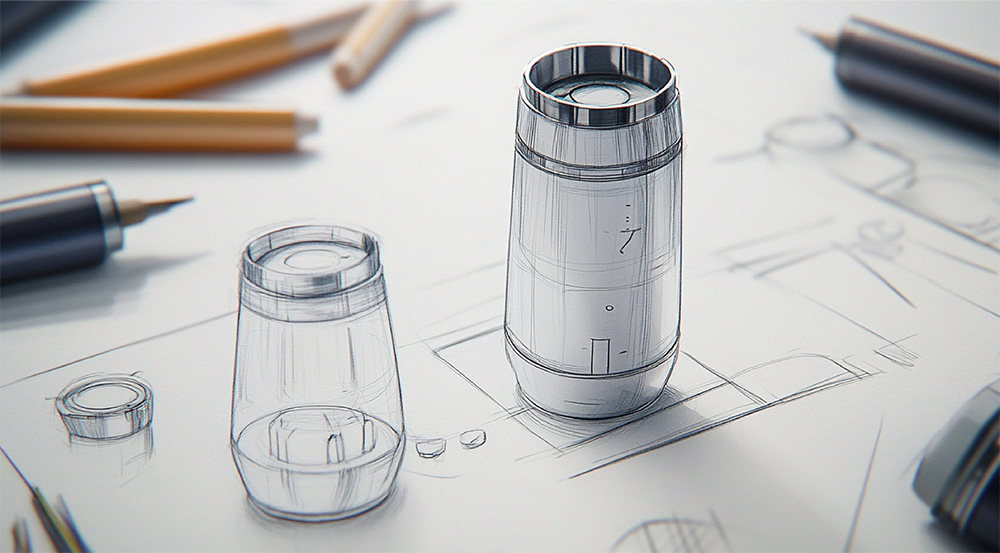

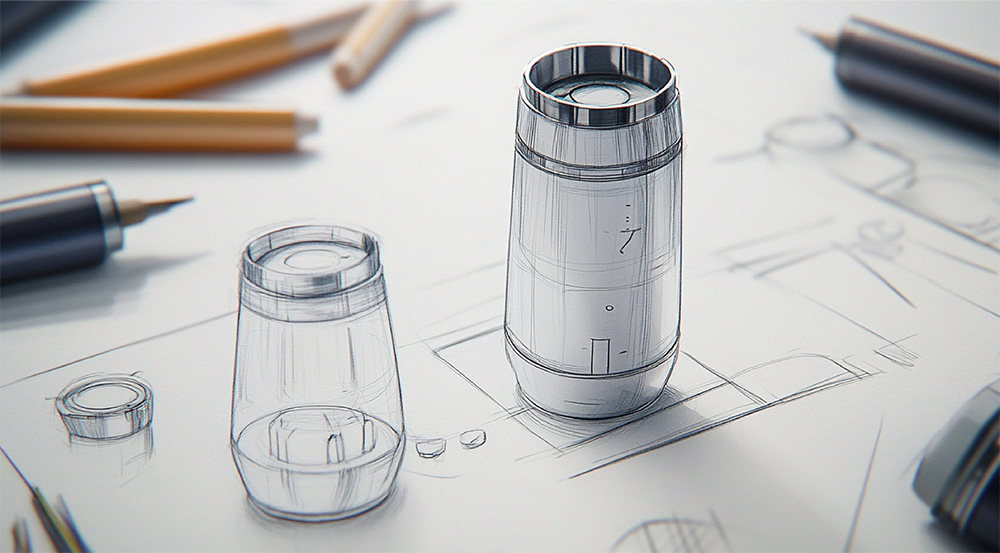

2. Sample Phase

In the sample stage, we finalize appearance, structure, prototype, and confirm the design for production readiness.

We create detailed 3D renderings and aesthetic designs for your review.

Structural design ensures the product’s durability, functionality, and user experience.

A high-fidelity prototype is built to verify design concepts.

Client feedback and confirmation mark readiness for mold development.

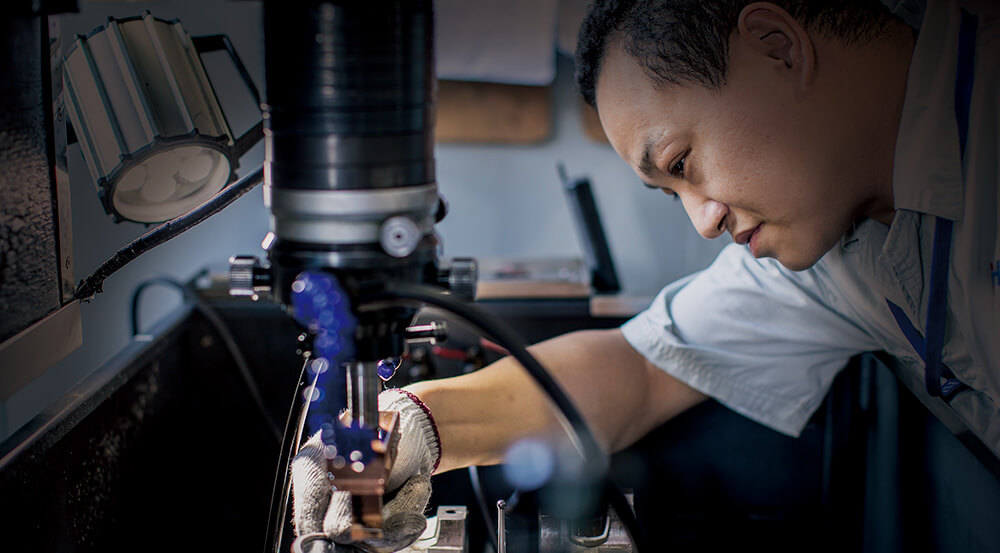

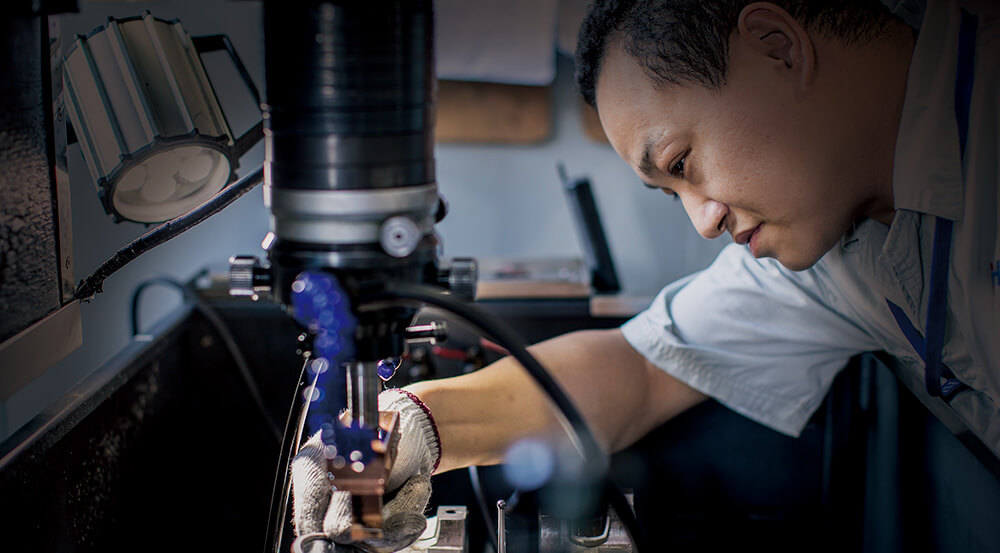

3. Trial Production

Coloring, tooling, sampling, and trial production are completed to confirm every detail before moving to full-scale manufacturing.

We develop the molds and perform precise color matching according to your specifications.

Sample production ensures molds, materials, and designs meet your standards.

We conduct a trial run to optimize the product and ensure smooth mass production.

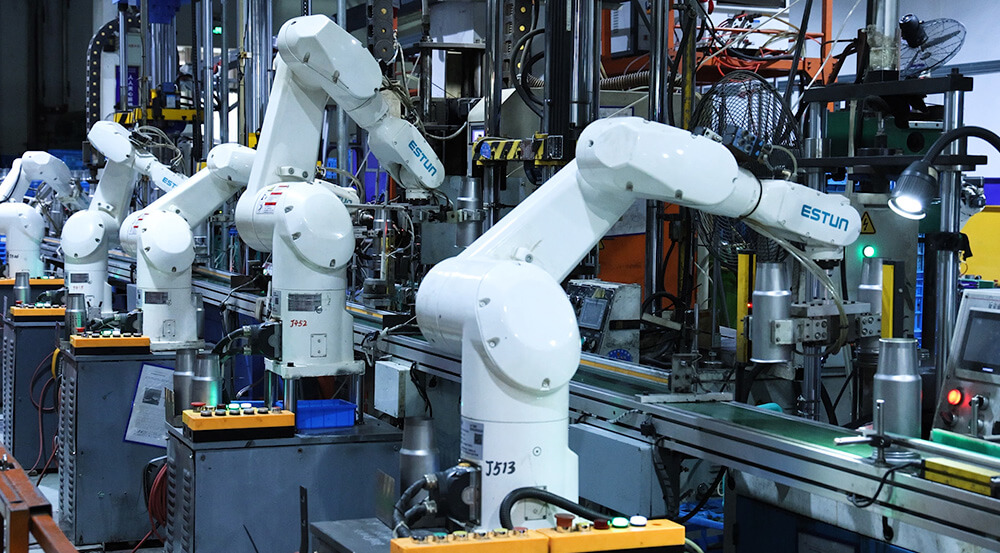

4. Scale Production

After completing 40 days of lab testing, we officially move into full-scale production to deliver consistent, high-quality products.

Products undergo comprehensive testing to meet international quality standards.

Upon final approval, we start large-scale production to deliver your custom products efficiently under Haers's quality control procedure.

Custom Water Bottle's Body Shape

Everything on the bottles can be customized, even the bottle's body shape. You can describe the bottle by idea, sketch, or even a concept. Haers' R&D team will do the rest for you.

Custom Water Bottle Surface

Haers provides more than 30 ways to paint the water bottle surface on stainless steel bottles, such as UV Painting, Ceramic Painting, Anodic Oxidation, Ice Flower Painting, Rubber Painting, and more.

Custom Water Bottle Lid

You can choose from the lid designs already in our collection or work with Haers’ in-house molding workshop to design and create a custom lid.

This is How OEM Process Works

From sketch to final product, customizing water bottle begins with your idea and your call.

Phase One

Starting with a concept and requirements, we collaborate to create design drafts, preview the product, refine it for feasibility, to produce the initial model.

Phase Two

The design and engineering teams create the design, then produce the first finished prototype for client approval. There are 4 steps in our process:

- Design the Product

- Structural Considerations & implementations

- Prototype design

- Sample Review

Phase Three

Through coloring, tooling, sampling, and trial production, we guarantee the product is fully optimized for stable mass production.

- Product Molding

- Sampling

- Trial Production

Phase Four

After completing 40 days of lab testing, we officially move into full-scale production to deliver consistent, high-quality products.

- Product Testing for 40 Days

- Scale Production

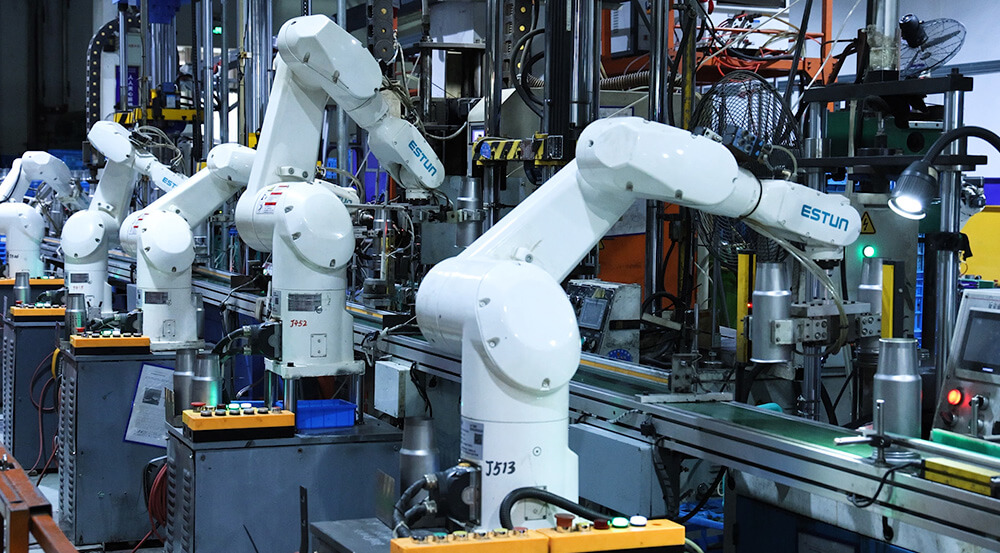

Unique craftsmanship & technology

With over 300 invention patents and design patents, customers are provided with unique designs and production solutions.

Quality control throughout production

From cutting, to pipe forming, hydroforming, shaping, rimming, polishing, welding, and many other processes, each step is subject to a strict quality inspection. After the trial production is completed, products undergo a rigorous 40-day laboratory testing process.

Type Test

Includes: Thermal insulation test, Drop test, Sealing performance test, Salt Spray Test, Sharp edge test, Strength test of back strap, Backstrap decolorization test and 40 more.

Physical Chemistry Test

Includes:Overall Migration, decoloring test, heavy metal, phthalate and Bisphenol A.

Material Test

Includes: Detection of stainless steel element content, Detection of plastic element content, Vickers hardness.

Ready to take your

business to the next level?

Get in touch today and receive the best OEM service you've ever had