ODM and OEM in Tumbler Manufacturing: A Deep, Practical Guide for Brands & Retailers

As a stainless steel tumbler manufacturer, we often hear the same question from new clients during our first discussions:

“What’s the difference between ODM and OEM for our project?”

Some buyers want speed, others want a bit of customization—and many aren’t sure whether their small modifications fall under ODM or OEM. Sometimes they don’t even realize that a simple change to the lid structure could significantly increase the budget.

So we decided to write a clear, simple guide to help brands and retailers understand the real differences between ODM and OEM in tumbler manufacturing, and choose the option that fits their goals and resources best.

Table of Contents

ToggleWhen OEM make sense?

In tumbler manufacturing, OEM (Original Equipment Manufacturer) means the brand provides the product design, while the factory handles production. This model is ideal for brands that already have a clear product concept, a mature identity, or the need for a fully customized tumbler structure. When clients come to us with drawings and expect a highly unique product, this is typically what we call OEM tumbler manufacturing.

OEM is Suitable For?

OEM is the best option for:

- Brands with established design teams

- Businesses planning a signature or patented tumbler

- Companies with a clear positioning and specific functional requirements

These buyers often choose OEM tumblers because they want full control over structure, insulation performance, lid mechanism, and packaging details.

Typical OEM Deliverables

When a brand chooses custom tumbler OEM service, they usually need to prepare:

- 2D or 3D design files (AI / CAD / PDF)

- Requirements on materials, thickness, and specifications

- Logo placement, color standards, and packaging requirements

These documents help us evaluate feasibility and provide accurate quotations.

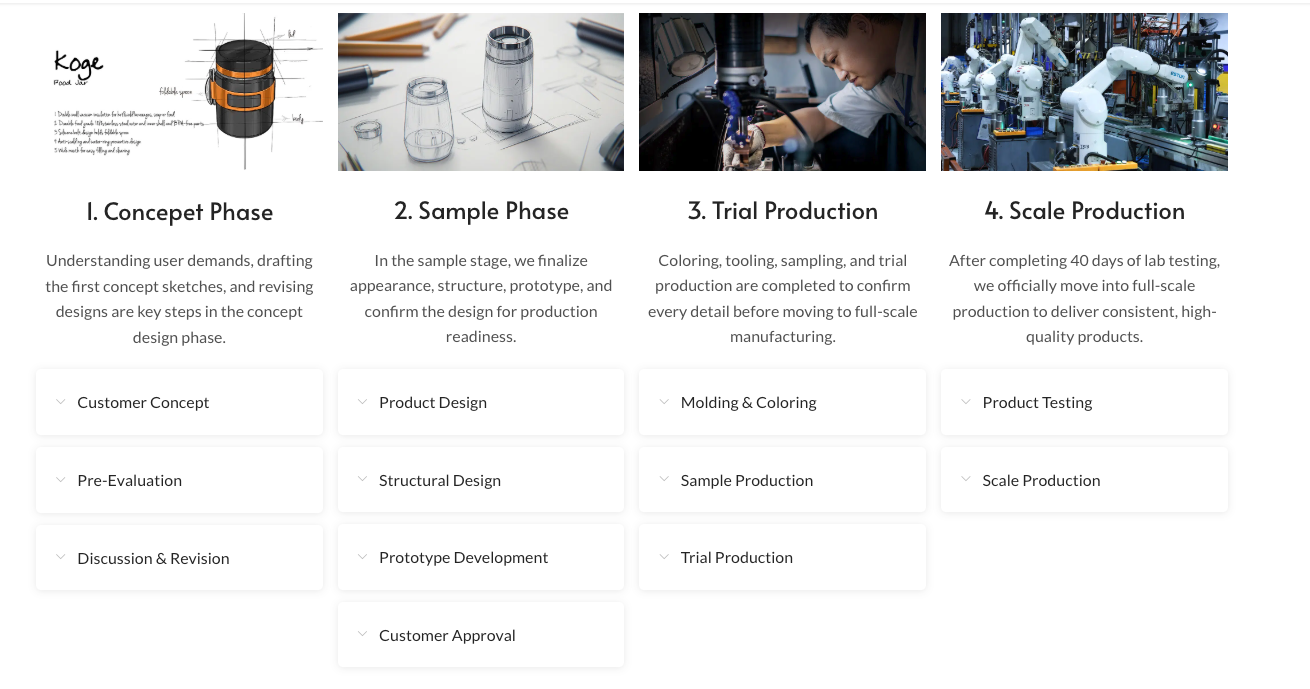

Our OEM Workflow (Detailed Version)

When you choose OEM with us, we turn your idea—no matter how rough—into a fully custom tumbler. Here’s the step‑by‑step workflow we follow at Haers:

Phase 1: Concept & Requirements

- We start by discussing your concept, requirements, and vision: capacity, materials, intended usage, design style, etc. We help you shape the initial concept.

- Our team conducts a technical pre‑evaluation to check feasibility, and we revise the concept together if needed.

Phase 2: Design & Prototype

- Our design and engineering team creates detailed 3D renderings and aesthetic designs of the bottle for your review.

- We finalize the product’s structure—wall thickness, insulation, lid mechanism, shape, ergonomics—ensuring durability, functionality, and a good user experience.

- Based on the approved design, we build a high‑fidelity prototype so you can see and feel exactly how the final product will be.

Phase 3: Molding, Sampling & Trial Production

- Once the prototype is approved, we proceed to build the tooling / molds, and conduct precise color matching and surface finishing according to your specifications.

- We produce sample units (first samples) to check that molds, materials, finishes, and structure meet your standards.

- We then run a trial production run to ensure the product and production line are optimized for stable mass manufacturing.

Phase 4: Lab Testing & Full‑Scale Production

- After trial production, bottles undergo a rigorous lab testing period (e.g. 40 days) to test insulation, sealing, durability, safety (material compliance), etc.

- Once all tests pass and quality is confirmed, we move into full-scale production. Under our strict quality‑control procedures, every bottle batch meets high standards before packaging and shipment.

Advantages of OEM

- Fully aligned with brand vision

The tumbler’s structure, lid type, insulation performance, and overall feel can be completely customized. - High controllability

Every detail—from material grade to bottom shape—is determined by the brand. - Higher long-term competitiveness

Unique molds and exclusive designs help brands stay ahead in the market.

Disadvantages of OEM

- Higher mold cost

Custom structures often require new tooling, abd the cost is usually paid by the brands. - Longer development timeline

Compared with ODM tumblers, OEM projects require more engineering and testing time.

What is ODM in Tumbler Manufacturing?

In the tumbler industry, ODM (Original Design Manufacturer) refers to a model where the factory provides ready-made water bottle designs, and clients simply customize colors, finishes, accessories, or add their logos. Unlike OEM, there is no need for expensive molds or full structural development, which makes the ODM Water bottle a fast and cost-efficient solution for many brands.

ODM is suitable for?

ODM is ideal for:

- New brands or startups wanting to enter the market quickly

- Companies with limited design resources or no in-house design team

- Brands seeking lower production costs and faster turnaround

Many retailers, corporate gift buyers, and e-commerce sellers use ODM drinkware suppliers to quickly get products ready for sale without the long lead times and high costs of OEM.

Who Benefits Most from ODM

When working with an ODM tumbler manufacturer, clients usually receive:

- Existing tumbler structures (no mold fees required)

- Optional colors and surface finishes

- Custom logo printing and packaging options

This allows brands to create a branded product quickly while keeping costs low.

Our ODM Workflow

- Select a ready-made design from the factory catalog

- Provide your logo files and branding specifications

- Choose colors, finishes, packaging and other optional accessories

- Sample confirmation to ensure logo placement, color accuracy, and finish

- Mass production once the sample is approved

This streamlined process is one of the main reasons ODM vs OEM is such a common question—ODM allows brands to test the market and launch products fast.

Advantages of ODM

- Shorter time to market – ready-made designs reduce development time significantly

- Lower cost – no mold fees or lengthy engineering required

- Reduced risk – proven designs have already been tested for functionality and durability

Disadvantages of ODM

- Limited structural customization – the base design cannot be heavily modified

- Shared designs – other brands may use the same ready-made tumbler, which reduces exclusivity

Common Misconceptions We’ve Seen (Experience-based Insights)

❌ “ODM costs next to nothing.”

In reality, while ODM eliminates mold fees, cost is still influenced by printing methods, materials, and packaging complexity.

❌ “OEM = delayed release.”

While true that OEM projects take longer, proper planning and a collaborative engineering process (not us waiting on specs) can keep development efficient.

❌ “ODM means zero customization.”

You can influence material choices, printing methods, and some finish options — but there are structural limits.

These are insights we’ve learned working with hundreds of brands in North America and Europe, where production detail clarity directly impacts satisfaction.

Key Differences Between ODM & OEM for Drinkware Brands

When brands are deciding between ODM vs OEM for their tumblers, the differences go beyond cost or speed. Understanding each model’s strengths and limitations can help you choose the approach that fits your business goals, budget, and timeline.

Here’s a quick overview of how OEM and ODM tumbler manufacturing compare across key factors:

| Factor | OEM (Custom Tumbler) | ODM (Ready-Made Tumbler) |

|---|---|---|

| Development Cost | Higher – new molds, engineering, and prototyping required | Lower – uses existing designs, no mold fees |

| Time to Market | Slower – full design and sampling process | Faster – ready-made designs can be customized quickly |

| Customization Depth | Full control – structure, lid, insulation, and accessories | Limited – mainly colors, finishes, and logo |

| MOQ | Usually higher due to tooling and production setup | More flexible, suitable for small batches |

| Brand Exclusivity / Differentiation | Complete originality – unique designs for your brand | Limited – other brands may use the same base model |

| Target Customers | Established brands, products needing high differentiation | New brands, startups, e-commerce sellers, promotional gifts |

This comparison clearly shows why OEM and ODM is not just a matter of cost: it’s about balancing speed, customization, and market strategy. Brands that need fully original custom tumblers often go with OEM, while those who want to launch quickly with proven designs may prefer ODM.

How to Decide: ODM or OEM for Your Tumbler Brand

Choosing between ODM and OEM ultimately depends on your brand’s goals, resources, and timeline. Both OEM tumbler manufacturing and ODM tumblers have clear advantages—but knowing which fits your business can save time, cost, and potential frustration.

Here’s a simple guide to help you decide:

Choose ODM If:

- You want fast market entry with minimal development time

- Your budget is limited and you want lower upfront costs

- You don’t have a full in-house design team

- You need a proven ready-made design that can be customized with your logo and colors

- You want smaller MOQs to test the market

Many startups, e-commerce sellers, and promotional gift buyers choose ODM drinkware suppliers to quickly get products ready for sale while minimizing risk. ODM is perfect when you want to launch quickly, maintain flexibility, and focus on marketing and distribution.

Choose OEM If:

- You want a fully custom tumbler with unique structure, lid mechanism, or insulation performance

- Your brand strategy requires high differentiation to stand out in the market

- You have clear product specifications or a design team ready to provide drawings

- You are prepared for longer lead times and higher initial investment

- You aim to build long-term brand identity and exclusivity

Brands that require originality, patents, or proprietary designs usually go for custom tumbler OEM, giving them full control over the product and helping create a competitive edge in the market.

Final Word

Deciding between ODM and OEM for your tumbler brand doesn’t have to be confusing. By understanding the differences in cost, customization, lead time, and brand exclusivity, you can select the approach that best fits your goals and resources.

- ODM tumblers help you enter the market quickly, minimize risk, and keep costs low.

- OEM custom tumblers give you full control over design, stand out in the market, and build long-term brand value.

At the end, the right choice depends on your brand’s stage, budget, and vision. Whether you’re looking for ready-made designs with simple branding or fully customized, original products, planning ahead ensures a smoother process and a product that truly represents your brand.

If you’re ready to start your tumbler project, we’re here to guide you through the process and help you choose the right solution for your business. Let’s create something your customers will love—and that stands out in the market.