How Are Tritan Water Bottles Manufactured?

At Haers, we are best known as a stainless steel drinkware manufacturer—but stainless steel bottle is not our only product line, while Tritan water bottles is another.

In parallel with our metal production, we operate multiple dedicated Tritan water bottle production lines. These lines are built around advanced processing technologies and refined mold design methods, allowing a single mold set to support a broader range of bottle specifications over its lifecycle.

By improving mold versatility and extending usable production cycles, we are able to generate more output from the tooling investment, while maintaining consistent quality at scale. This approach is especially valuable for brands that evolve their product lines gradually, rather than launching everything at once.

Understanding how Tritan water bottles are made helps explain why they look the way they do—and why certain designs work better than others.

Table of Contents

Toggle- 1. What Is Tritan Material?

- 2. The Manufacturing Logic Behind Tritan Water Bottles

- 3. How Tritan Bottle Bodies Are Formed

- 4. Why Tritan Bottles Have a Uniform Shape

- 5. How Tritan Bottle Lids Are Made

- 6. Handle Design for the Tritan Bottle

- 7. Printing on Tritan Bottles

- 8. Key Differences Between Tritan and Stainless Steel Bottle Manufacturing

- 9. Final Assembly and Quality Control of Tritan Water Bottles

- 10. Common Uses of Tritan Water Bottles in the Market

1. What Is Tritan Material?

Tritan is a BPA-free plastic developed for food-contact applications where safety and durability are non-negotiable.

One of Tritan’s most recognizable features is its exceptional clarity. Visually, it comes close to glass, yet without the fragility or weight. At the same time, it offers strong impact resistance and stable performance under repeated daily use.

These characteristics make Tritan particularly suitable for drinkware products that are handled frequently, dropped occasionally, and expected to remain visually clean over time. This is why Tritan has become a common material choice for baby bottles, children’s cups, and reusable water bottles.

From a manufacturing perspective, Tritan also behaves consistently during forming, which allows manufacturers to maintain tight quality control across large production.

2. The Manufacturing Logic Behind Tritan Water Bottles

Once the material is defined, the manufacturing logic of a Tritan water bottle becomes much clearer.

Unlike stainless steel bottles, which are hydro-formed, joined, and finished through multiple mechanical processes, Tritan bottles are shaped through plastic forming methods that create a hollow structure in a single step. This approach naturally influences both the structure and appearance of the final product.

A typical Tritan water bottle is built around three core production elements:

the bottle body, the bottle lid, and the final assembly that brings them together.

Because the bottle body is formed as a uniform hollow piece, its geometry tends to be clean and balanced. Straight sidewalls, smooth curves, and consistent wall thickness are not just aesthetic choices—they are direct results of how the material is processed.

This is also why many design decisions for Tritan bottles are made early in development. The material and forming method set clear boundaries, guiding what can be integrated into the bottle body itself and what is better handled through separate components such as the lid.

3. How Tritan Bottle Bodies Are Formed

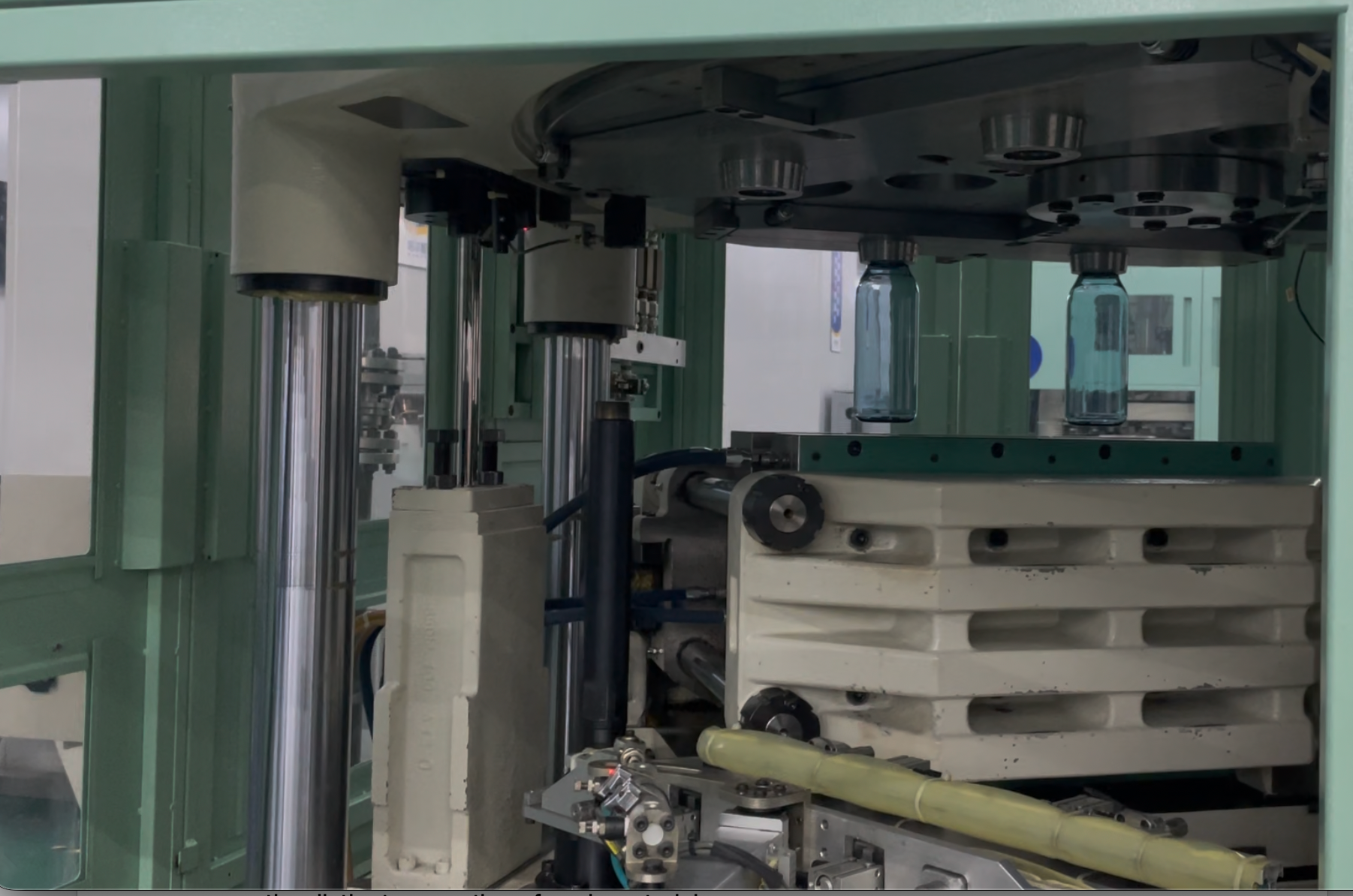

In Tritan water bottle production, the bottle body is formed through an integrated blow molding process that defines the final structure in one machine.

During forming, the Tritan material is automatically conveyed through enclosed pipelines from the raw material processing system to the blow-molding machine. There is no manual intervention in between—just a continuous, controlled flow of molten material moving through the line.

In a matter of seconds, the heated, bottle-shaped preform is expanded and transformed into a hollow bottle. The entire blow-molding process is fully automated. It may feel almost magical the first time you see it, but in reality, this is exactly how efficient plastic forming is designed to work.

Through this one-step molding process, the bottle body is shaped cleanly and quickly. By the time the blowing cycle is completed, the bottle has already stabilized both dimensionally and visually. What comes out of the mold at that moment is, in essence, the finished Tritan bottle body.

Because the molding process is strictly controlled, the bottle exits the mold clean and consistent. The surface is free from excess material, and the shape does not require secondary refinement. This is why Tritan bottle bodies maintain such a high level of crystal clear during the production—the form is fully determined at the moment of molding, not adjusted afterward.

This one-step approach also reinforces the structural simplicity of Tritan bottles, the bottle body is designed to reach its final state directly during forming.

4. Why Tritan Bottles Have a Uniform Shape

Once the forming method is understood, the uniform shapes of Tritan water bottles start to make sense.

Because the bottle body is shaped as a single, hollow structure, its geometry naturally follows balanced and symmetrical lines. Straight sidewalls, smooth transitions, and evenly distributed curves are not stylistic choices imposed after the fact—they are outcomes of how the material behaves during forming.

While Tritan bottles can adopt slight variations in shape, these changes remain controlled and evenly distributed. Irregular or highly complex external features cannot be integrated into the bottle body itself. Unlike stainless steel bottles, which allow handles or brackets to be welded or assembled onto the body later, Tritan bottles must maintain structural continuity throughout the forming process.

Transparency further defines the aesthetic of Tritan bottles. The material’s natural clarity is typically preserved, and even when color is added, it is applied in light or translucent tones. This allows the bottle to retain its high-transparency appearance, reinforcing the perception of cleanliness and material purity.

5. How Tritan Bottle Lids Are Made

In water bottle manufacturing, material selection for the lid follows a different logic than the bottle body.

5.1 Why PP Is Commonly Used for Tritan Bottle Lids

Although Tritan can be used to produce lids, it is more commonly applied in combination with stainless steel bottles rather than Tritan bottle bodies. For Tritan bottles, brands typically choose PP (polypropylene) for the lid.

From a design standpoint, PP offers greater freedom in color expression. Its ability to support rich, saturated colors creates visual contrast when paired with a highly transparent Tritan bottle body. This balance between clarity and color has become a widely accepted design code in the market.

From a functional perspective, PP is also better suited for complex lid structures that require flexibility, durability, and reliable sealing performance.

5.2 Lid Production as a Component-Based Process

Unlike the bottle body, a Tritan bottle lid is the result of component assembly, not single-piece molding.

Modern bottle lids—especially those designed with advanced or multifunctional drinking mechanisms—are made up of many individual parts. Depending on the design, a single lid can consist of dozens of components. In more complex cases, such as lids offering multiple drinking options, the number of parts can reach several dozen in some instance, each serving a specific mechanical or sealing function.

The manufacturing process begins with injection molding each component separately. Once produced, these parts are assembled step by step into a complete lid structure. Only after this assembly process does the lid become the unified component that users interact with.

This modular approach allows lid designs to evolve independently of the bottle body, enabling more sophisticated functionality without changing the fundamental structure of the Tritan bottle itself.

6. Handle Design for the Tritan Bottle

Given the structural characteristics of Tritan bottle bodies, handles are designed as part of the lid system rather than the bottle itself.

In most Tritan water bottles, the handle is integrated with the lid or assembled as a lid-mounted component. It is produced during the same injection molding stage as other lid parts and assembled together as part of the complete lid structure.

This separation of roles allows the bottle body to remain clean, uniform, and transparent, while the lid—and its attached handle—provides usability and visual contrast. It also gives designers more flexibility to refine grip comfort and portability without affecting the integrity of the bottle body.

7. Printing on Tritan Bottles

Tritan’s material characteristics also influence how bottles are decorated. The most common printing methods used on Tritan bottles are machine printing and screen printing, both of which work well with the smooth, high-transparency surface of the material.

Because one of the main reasons brands choose Tritan is its crystal-clear appearance, printing is usually kept minimal and simple. Excessive graphics or large opaque areas would obscure the material’s natural clarity, which is part of the bottle’s visual appeal. As a result, most Tritan bottles feature only modest logos, subtle patterns, or small design elements, allowing the transparency of the bottle to remain the focal point.

8. Key Differences Between Tritan and Stainless Steel Bottle Manufacturing

While Tritan and stainless steel bottles may serve similar end uses, the manufacturing processes behind them are fundamentally different, reflecting the distinct properties of each material.

Insulated stainless steel water bottles are typically produced with a double-wall structure, which introduces several additional steps. After forming the inner and outer walls, the two layers must be welded together and the space between them often evacuated to create a vacuum for insulation purposes. These processes require precision welding equipment and careful handling to maintain structural integrity and ensure consistent thermal performance.

Beyond structural formation, stainless steel bottles offer a wide variety of surface finishing options. Brands can choose from brushed, polished, painted, or powder-coated finishes, allowing for diverse aesthetics. Additional decorative elements, such as handles or metal attachments, can also be incorporated after the main forming process, giving designers greater freedom in structural and visual customization.

In contrast, Tritan bottles follow a much simpler production logic. The bottle body is formed in a single-step blow-molding process, which can incorporate color directly into the material. This approach eliminates the need for welding, vacuuming, or multi-stage finishing. Any decorative elements are typically added through simple printing techniques, such as machine printing or screen printing, rather than complex coatings. Because the primary appeal of Tritan bottles is their high transparency, most brands choose only minimal or subtle graphics, allowing the clarity of the material to remain the main visual feature.

In short, stainless steel bottles offer structural complexity and diverse surface treatments, while Tritan bottles provide simplicity, transparency, and efficient production. Understanding these differences helps brands choose the right material based on design goals, cost considerations, and intended use scenarios.

9. Final Assembly and Quality Control of Tritan Water Bottles

After the bottle body is formed and the lid components are ready, the Tritan water bottle moves into the final assembly stage. Unlike stainless steel bottles, which may require welding, vacuuming, or multiple finishing steps, Tritan bottles are designed for streamlined assembly.

The pre-formed bottle body is paired with a fully assembled lid, which often includes handles, valves, or other functional elements. The lid is attached according to strict tolerances to ensure proper fit, leak-proof performance, and smooth operation. Because the bottle body is already stabilized during blow molding, no structural adjustments are necessary at this stage.

Quality control focuses on both visual inspection and functional checks. The transparency of Tritan makes it easy to identify any defects, internal bubbles, or foreign particles. Additionally, lids with complex drinking mechanisms are tested to ensure proper flow and sealing. Once a bottle passes these checks, it is cleaned, dried, and packaged, ready for the consumer.

This assembly process highlights the efficiency of Tritan bottle production: one-step molding for the body combined with modular lid assembly creates a finished product quickly, consistently, and with minimal post-processing.

10. Common Uses of Tritan Water Bottles in the Market

The production characteristics of Tritan bottles directly influence the markets and user scenarios where they excel.

- Children’s bottles and baby bottles: Tritan’s high transparency, impact resistance, and BPA-free properties make it ideal for parents seeking safe and easy-to-monitor drinkware. Minimal printing or subtle designs preserve clarity and hygiene perception.

- Sports and outdoor bottles: Lightweight, durable, and easy to carry, Tritan bottles with functional lids—such as flip tops, straws, or multi-mode drinking mechanisms—meet the needs of active users. The streamlined body and modular lid design allow for reliable performance during repeated use.

- Everyday hydration bottles: Office, school, or commuting bottles benefit from Tritan’s transparency and clean look. The simplicity of blow-molded bodies combined with customizable lids provides practicality without compromising visual appeal.

In each scenario, Tritan bottles leverage the material’s clarity and safety while delivering a product that is both functional and aesthetically pleasing. Unlike stainless steel bottles, they are lighter, more transparent, and simpler to produce at scale, making them a practical choice for a wide range of applications.

Integrated forming defines the bottle body in a single step, while functionality and interaction are handled through a multi-component lid system. The whole process is some kind of similar to the manufacturing process of glass water bottles.

With fewer production steps than stainless steel water bottles and lower raw material costs, Tritan water bottles are generally more affordable. At the same time, Tritan’s crystal-clear appearance positions it as a more premium plastic option compared with standard PP bottles. For brands, choosing between stainless steel and Tritan is less about right or wrong, and more about understanding the intended use scenarios.