How Are Colorful Metal Cups Made Without Paint?

Consumers today love colorful metal cups, but few realize how most colors are created — with layers of paint or powder coating. These methods look bright at first but don’t always last long and aren’t the most sustainable choice.

At the same time, there’s growing awareness about how those colors are made. Many customers — especially in Europe and North America — are asking whether the coatings on their bottles or tumblers are safe, durable, and environmentally friendly.

That’s where a new kind of design innovation comes in. Instead of using chemical paints or coatings, some water bottle manufacturers are turning to paint-free color technology to achieve stunning, lasting shades. And one of the leaders in this shift is us, a stainless steel cup manufacturer for 25 years history in China.

Table of Contents

ToggleWhat’s the common painting method for dinkware?

Most colorful metal cups on the market still rely on water transfer, powder coating, or digital printing to achieve their finish. These methods can create bright, glossy looks — but they also come with trade-offs that matter to both brands and the planet.

Traditional painting or coating can:

- Depend on chemical pigments that release emissions during production.

- Fade or peel after long-term use or repeated washing.

- Add environmental impact, making recycling more difficult.

For retailers and promotional gift companies, that means more quality issues, shorter product lifespans, and less sustainable appeal. A cup that looks great at first might lose its color within months — and that’s the last thing any brand wants its logo printed on.

This is why forward-thinking manufacturers like Haers are exploring alternatives. Instead of applying color on top of metal, they’re learning how to create color from the metal itself — a cleaner, smarter, and more durable way to design.

The Science Behind “Color Without Paint“

So, how exactly can stainless steel or titanium show color without using paint?

The secret lies in a technology called anodizing — a surface treatment that changes the way light interacts with metal.

During the anodizing process, the metal is placed in an electrolytic bath and an electric current is applied. This forms an ultra-thin oxide layer on the surface. By carefully controlling the voltage and time, the thickness of this oxide layer changes — and so does the color you see.

Here’s the fascinating part:

- No pigments or dyes are added.

- The colors come purely from light interference, similar to how soap bubbles or butterfly wings reflect rainbow hues.

- Each variation in layer thickness reflects light differently, producing vibrant shades of blue, gold, purple, or green — all created by nature’s physics, not paint.

This technique isn’t new in aerospace and high-end electronics, but Haers has taken it further — applying it to stainless steel and titanium drinkware at a commercial scale. By refining the anodizing process, Haers can precisely control color tones and surface patterns, turning every cup into a unique metallic artwork.

The result is a durable, eco-friendly finish that won’t peel, fade, or release any harmful substances. It’s color built into the metal itself — not a layer on top of it.

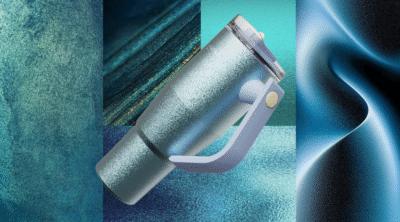

Haers’ Titanium Cup Series with No-painting Color

At Haers, color innovation is more than surface beauty — it’s a reflection of craftsmanship and research. This philosophy came to life in the brand’s Cuiran Series Titanium Cup, which won the 2024 International CMF Design Award for its breakthrough in color, material, and finish.

Inspired by the stained-glass artistry of Sainte-Chapelle in Paris, Haers’ design team reimagined how light and metal could interact. Using advanced anodizing technology, we divided the cup surface into multiple geometric sections, each catching and refracting light differently. The result is a dazzling gradient of colors that shift as you move the cup — much like sunlight streaming through stained glass.

Unlike conventional coatings, this finish isn’t applied; it’s engineered directly into the titanium. Every hue, from vivid violet to shimmering gold, is controlled by adjusting oxidation levels during production. It took Haers more than six months of development and testing to perfect this process — a project fully designed and developed in-house.

The outcome is a titanium drinkware collection that merges artistic expression with industrial precision. Each piece feels like a functional artwork: lightweight, corrosion-resistant, and brilliantly colored without a single drop of paint.

Haers’ award-winning titanium cups don’t just redefine what stainless steel drinkware can look like — they also set a new standard for sustainable design in the global drinkware industry.

Sustainable Manufacturing: Less Paint, Less Pollution

Behind every colorful Haers cup is a clear purpose — to make cups sustainable.

Traditional painting and coating processes often rely on chemical pigments and solvents that can release emissions, generate waste, and complicate recycling. By removing these materials entirely, the anodizing process marks a real step forward for the drinkware industry.

The titanium anodizing method used in Haers’ Cuiran Series doesn’t require any chemical dyes or surface coatings. Instead, color is created through controlled oxidation, which means:

- No chemical pollution in the coloring stage.

- Lower carbon emissions compared to conventional coating lines.

- Longer product lifespan, reducing material waste over time.

This aligns with Haers’ ongoing commitment to China’s national “3060 dual-carbon goals” — achieving carbon peak by 2030 and carbon neutrality by 2060. For international partners, it means sourcing drinkware from a manufacturer that values environmental responsibility as much as product quality.

In a global market increasingly shaped by green procurement and ESG standards, Haers’ approach provides retailers, brands, and gift buyers with a powerful advantage: eco-friendly stainless steel cups that meet modern sustainability expectations — without sacrificing beauty or performance.

Why This Matters for Retailers and Brands

For retailers, gift suppliers, and brand owners, the way a product looks — and how it’s made — directly impacts customer perception and sales. Haers’ paint-free titanium cups offer multiple advantages that make them ideal for international markets:

- Unique and Premium Design: Vivid colors, light-reflecting surfaces, and intricate geometric patterns create a visually striking product that stands out in crowded shelves or promotional campaigns.

- Durable and High-Quality: Anodized colors won’t peel, fade, or scratch easily, ensuring that branded logos and custom designs maintain their premium appearance over time.

- Eco-Friendly and Sustainable: Paint-free manufacturing reduces chemical use and carbon emissions, meeting the growing demand for environmentally responsible products.

- Customizable at Scale: Haers’ in-house R&D and production capabilities allow for flexible OEM and ODM options, perfect for large or small batch orders with logos, colors, and designs tailored to your brand.

By choosing Haers, brands can offer consumers stunning, long-lasting drinkware while demonstrating environmental responsibility — a combination increasingly valued in today’s global gift and retail markets.

This is more than just a cup; it’s a product that blends innovation, sustainability, and style, helping your brand stand out while staying ahead of market trends.