How to Source Fully Customized Water Bottles from Factories?

Walk into any outdoor store, gym, or scroll through social media, and you’ll notice the same story repeated: bottles with similar shapes, similar spouts, and just a logo swapped in. Retail brands that want to stand out can no longer rely on generic options. This is where fully customized water bottles come in. By designing every aspect—from shape and lid style to materials and surface texture—brands can create bottles that feel unique, functional, and truly their own.

Consumers today expect more than just a logo. They want a distinct look, a comfortable hand-feel, smarter functionality, and an experience they recognize instantly. Fully customized bottles allow you to deliver all of that, while also strengthening brand identity, supporting premium pricing, and encouraging repeat purchases. If you want your brand to be remembered—not just recognized—a fully customized water bottle is the path forward.

Table of Contents

Toggle- What Does “Fully Customized Water Bottle” Really Mean?

- What Should a Brand Clarify Before Approaching an OEM Factory?

- How to Find and Identify a Factory with Real Fully Customized (OEM) Capabilities

- How to Evaluate a Factory’s Fully Customized (OEM) Capability

- The OEM Customization Process

- Common OEM Pitfalls — and How to Avoid Them

What Does “Fully Customized Water Bottle” Really Mean?

When we say fully customized, we’re talking about more than colors, printing, or logo. A fully customized water bottle is built from the ground up, based on your concept, target users, and brand positioning. It allows you to rethink the bottle in both form and function, including:

1. Structure & Shape

- Slim, wide, square, or signature curves

- Custom handle geometry

- Locking systems, lid mechanisms, hidden straws, one-hand open designs

- Unique body ratios and silhouettes (not shared with competitors)

2. Material Choices

- Stainless steel (304 or 316 for premium insulation)

- Tritan for BPA-free clarity

- Titanium

- Glass, silicone, or hybrid material combinations (Chosen based on branding, cost, user experience, and target market regulations)

3. Surface & Texture

- Powder coating, soft-touch coating, brushed metal, polished, matte, or gradient

- Pattern textures, grip textures, or tactile finishes that become a brand signature

4. Functional Performance

- Insulation hours, leak-proof structure, straw diameter, drinking angle, grip size, capacity, and lid style

- Custom features like carabiner hooks, measurement lines, or lock buttons

5. Branding & Packaging

- Pantone-matched colors

- Private label packaging, insert cards, sleeve boxes, custom-mold bottle caps or medallions

- A complete unboxing experience that feels “premium and memorable”

In factory language, this level of development is an OEM project, supported by product engineers, 3D modeling, mold building, pilot runs, and strict testing. It requires real manufacturing capabilities — which is why gift suppliers and trading companies cannot offer true “fully customized” services. They typically only provide:

- Logo printing (screen print, laser engraving, Digital printing, etc.)

- Color options from existing molds

- Limited accessory changes

| Custom Type | Scope | Supplier Type | Best For |

|---|---|---|---|

| Logo/Color Customization | Surface-level changes | Gift supplier / trading company | Promo or budget projects |

| Fully Customized (OEM) | Structure, materials, tooling, performance, branding | Water bottle factory with engineering departments | Retail brands, DTC, long-term product lines |

To build a bottle that people remember — not just recognize — fully customized OEM development is the approach that gives a brand its own identity, not a borrowed one.

What Should a Brand Clarify Before Approaching an OEM Factory?

Before contacting a factory for a fully customized project, brands should have a clear direction — not a perfect design, but at least a well-defined intent. A factory can turn ideas into a real product, but the brand must first decide who the bottle is for, what problem it solves, and how it should feel in the customer’s hand. Here are the key elements to prepare:

1. Target Market & Compliance Requirements

Different markets = different regulations and testing requirements.

For example:

- U.S. usually requires FDA food-contact compliance

- EU often follows LFGB, which has stricter material standards

- Kids cups may also involve BPA/Phthalates restrictions

If the bottle is for outdoor, gym, kids, coffee lovers, or office use, tell the factory — it affects structure, materials, and testing standards from day one.

2. Product Direction & Functionality

Share preferences such as:

- Flip-top, straw lid, spout lid, twist cap, or one-hand open

- Leak-proof priority or lightweight priority

- Capacity range (e.g., 500ml / 700ml / 40oz)

- Any “must-have” or “must-not-have” features

3. Material Preference & Brand Positioning

- Stainless steel for premium insulation

- Tritan for lightweight and BPA-free clarity

- Titatiumn for next-level outdoor bottles

- Silicone or mixed materials for lifestyle look and feel

This decides cost, performance, and even customer perception.

4. Expected Budget and MOQ

OEM projects require molds, engineering work, and testing.

- If the budget is very low, fully customized may not be realistic

- If the budget is reasonable, factories can recommend smarter structural solutions to reduce cost while keeping brand uniqueness

5. Timeline Expectations

From design to mass production, OEM bottles typically take 90–150 days, depending on complexity. If a customer needs something in 2–3 weeks, they should choose an existing model, not full customization.

In short: Before approaching a factory, a brand doesn’t need a final blueprint — but should at least have a concept, a direction, and realistic expectations in budget and timeline.

How to Find and Identify a Factory with Real Fully Customized (OEM) Capabilities

When sourcing a fully customized bottle, the first challenge isn’t price or design—it’s finding a supplier that is truly capable of OEM development. Many companies in the market claim they “support customization,” but in reality, they only offer logo printing. So the goal is not to find a factory supplier quickly, but to find the right type of partner: a factory that can turn concepts into real, mass-produced products.

You can start from common channels—Google searches, industry exhibitions, or B2B platforms—to build your initial supplier list. But the real work begins after the first contact. A genuine OEM factory will always show signs that they are manufacturing-driven: they have in-house engineers, experience with mold development, and the ability to discuss structure, not just surface customization. During communication, observe what they emphasize. If a supplier only talks about colors, logo methods, and unit prices, they’re likely a trader or a gift supplier. By contrast, a real factory will naturally ask about functional requirements, insulation expectations, drinking mechanisms, materials, testing standards, and end-user scenarios—because these details determine how the product must be engineered.

Another key indicator is transparency. OEM factories are usually willing to show their production workshops, quality-control processes, mold photos, or past custom projects. They can explain how they manage testing (such as leak-proof, drop, or insulation tests) and what certifications they support for your target market (FDA, LFGB, etc.). This is fundamentally different from suppliers who only send a catalog and continue pushing you to “choose a model.”

In short, sourcing a fully customized bottle means looking for engineering depth, manufacturing capability, and case-proven OEM experience—not just nice product photos. Once you identify a partner who can truly design, tool, produce, and control quality in-house, the project becomes predictable and scalable, rather than risky and improvisational.

How to Evaluate a Factory’s Fully Customized (OEM) Capability

Once you’ve shortlisted a few potential suppliers, the next step is to evaluate the depth of their manufacturing strength. This stage matters because fully customized development isn’t about “whether they have a factory,” but whether their factory can handle engineering, mold development, and scalable production without trial-and-error at your expense.

A legitimate OEM bottle factory will always demonstrate three types of capabilities: engineering capability, tooling capability, and manufacturing capability. If any one of these is missing, the risk of project delays, quality issues, or cost overruns will multiply later.

Start with the factory’s engineering and R&D strength. With fully customized bottles, structure comes before appearance. A capable factory should be able to discuss wall thickness, insulation structure, leak-proof mechanics, lid tolerances, and 3D modeling—not just Pantone color or coating styles. You can simply ask who designs the structure and who prepares the drawings. If their answer is “we outsource,” then they are not a true OEM partner.

Next, confirm mold development capability. New bottle shapes require new tooling, and tooling requires experience. An OEM factory should be able to explain mold timelines, mold materials, expected tolerances, and potential structural risks in advance. You can also request photos or case references of molds they’ve built before—this quickly separates factories with real OEM experience from those who only customize surface finishes.

Finally, assess real production capacity and quality control. A fully customized bottle passes through many stages—stretching, welding, polishing, coating, assembly, leak testing, and packaging. If a supplier cannot show production workshops, QC processes, or testing reports, they may not be the one building your bottle. A strong OEM factory will show confidence in its supply chain control, because stable in-house production is what ensures consistent quality and reliable lead time.

The OEM Customization Process

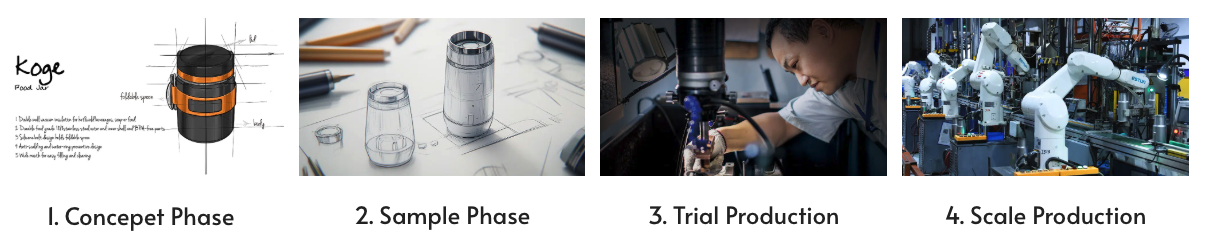

Once you’ve identified the right OEM factory, the development journey becomes a structured process. A fully customized bottle typically goes through six major phases, each one moving the concept closer to a shelf-ready product:

1) Concept & Requirement Alignment

This is where everything starts. The brand shares its vision, target users, intended functions, capacity range, materials, and market requirements. The factory evaluates feasibility and proposes structural direction to ensure the idea can be engineered and mass-produced.

2) Industrial Design & 3D Engineering

Based on your concept, the factory develops product drawings and 3D models. At this stage, aesthetics and functionality merge — lid mechanics, insulation structure, wall thickness, and ergonomics are optimized while keeping your brand DNA intact.

3) Tooling & Sample Development

After the design is approved, mold building begins. The first samples (T0/T1 samples) are produced for functional review — to check grip feel, sealing, straw performance, sipping angle, lid fit, and overall proportions. Adjustments are made before entering mass production.

4) Testing & Certifications

Before scaling up, the sample goes through key tests such as leak-proof testing, drop testing, dishwasher simulation, and insulation performance checks. Depending on your target market, the factory also prepares compliance support for FDA, LFGB, Proposition 65, or other standards.

5) Mass Production & Quality Control

Once testing is passed, the factory begins full production — stretching, welding, polishing, coating, printing, assembly, and final inspection. A reliable OEM partner will conduct layer-by-layer QC, not just a final-stage inspection.

6) Packaging & Shipment

After assembly and logo branding, your packaging, inserts, barcodes, and labels are applied. The products are then packed according to your shipping method — whether it’s palletizing for retail distribution or bulk packing for fulfillment warehouses.

Compared with simple logo customization, this OEM workflow requires deeper engineering coordination — but it results in a truly exclusive product that your competitors cannot source from any catalog.

Common OEM Pitfalls — and How to Avoid Them

Even with a good product idea and a capable supplier, OEM projects can still go off-track if expectations are misaligned. Most issues don’t come from manufacturing errors, but from unclear communication or missing details early in the process. To keep your project on time, on budget, and on quality, here are the most common pitfalls to avoid:

Pitfall 1 — Only discussing “looks,” not “function”

Many brands focus on appearance but forget to define drinking experience: leak-proof expectations, insulation hours, one-hand open needs, straw diameter, weight balance, etc. Function should always be clarified before design is finalized.

Pitfall 2 — Choosing the cheapest factory instead of the right factory

Fully customized bottles are not commodity printing orders. The cheapest quote often means outsourced engineering, weak testing, or unstable supply chain. Low upfront cost can lead to high after-sale cost.

Pitfall 3 — No clarity on testing or compliance requirements

Every market has its own rules. If compliance is not addressed early, you may face re-testing, shipment delays, or inventory losses at customs. Always align required standards (FDA, LFGB, Prop65, etc.) before sampling.

Pitfall 4 — Rushing timeline and skipping sample iterations

Custom tooling and engineering need time. If a brand rushes the project and skips proper testing or sample validation, the product risk transfers into mass production. A good factory will insist on getting the sample right — not just getting it fast.

How to avoid these risks:

- Be clear and detailed up front

- Choose suppliers based on engineering, not catalog size

- Confirm testing plans before tooling

- Always validate function, not only appearance, during sampling

OEM success is not luck — it’s process discipline + a capable factory + clear alignment.

A fully customized water bottle is more than a container — it’s a brand asset. In a market filled with look-alike shapes and copy-paste lids, owning your design gives you pricing power, differentiation, and long-term customer loyalty. By preparing your product direction, selecting a true OEM partner, and following a structured development process, your brand can bring a unique, high-quality bottle to life — one that no competitor can simply source from a catalog.

If you’re planning to develop a fully customized bottle and want to work directly with a manufacturer that designs, tools, and produces in-house, we’re here to help. As an OEM water bottle factory, Haers supports brands through the entire journey — from concept, engineering, and mold development to testing, mass production, and packaging.

Feel free to reach out to us for a consultation or project review. We’re happy to evaluate your idea and provide professional suggestions for structure, materials, and production feasibility.