What Kind of Drinkware Partner to Choose in the New Global Landscape?

Amid profound adjustments in global industrial chains and rapidly diversifying consumer demands, selecting a manufacturing partner capable of resisting regional production fluctuations while swiftly responding to customization needs has become critical for brands to build core competitiveness. From the foresight of supply chain layout to flexible production systems, from internationally recognized quality standards to sustainable green manufacturing practices, every choice impacts a brand’s market performance and long-term growth. As a leader in the industry for many years, Haers provides international customers with a preferred solution to adapt to the complex market environment with the layout of “Global Manufacturing + Local Intelligence”, and the “logic of choice” behind it is an important reference to cope with the current industry trends: Have you defined clear standards for choosing a drinkware manufacturing partner in today’s complex global environment?

Table of Contents

ToggleHow to Select a Drinkware Manufacturer Under New Conditions?

1. What Challenges Define the Current Drinkware Industry?

The global drinkware sector faces multi-dimensional complexities:

Restructured Supply Chains: Regionalization accelerates, with localized production bases rising in Southeast Asia, Central-Eastern Europe, and other regions, complementing China’s mature industrial chains.

Technology-Driven Competition: Demand shifts from basic functionality to scenario-based, personalized, and health-oriented solutions, driving upgrades in premium materials and smart technologies.

Heightened Sustainability Compliance: Recycled material adoption, clean energy production, and international safety certifications become market-entry prerequisites.

Geopolitical Dynamics: Regional production risks coexist with cross-border e-commerce opportunities, shifting competition from cost to a mix of technology, compliance, and supply chain resilience.

In this context, selecting a manufacturer requires a focus on supply chain resilience, technical adaptability, compliance, and green manufacturing to address diverse demands and complexities.

2. Supply Chain Resilience

Prioritize factories with localized production bases near key consumer markets. A “regional hub + local response” distributed network reduces overreliance on single regions, shortens delivery cycles, enhances order flexibility, and supports rapid small-batch, multi-category production shifts.

3. Technical Adaptability for Diverse Scenarios

Examine whether the manufacturer has technical solutions covering multiple scenarios such as outdoor, business, health, mother and baby, including core technologies such as long-lasting heat preservation, lightweight materials, intelligent sensor integration, and a rich library of CMF processes to ensure that the products are suitable for the functional and aesthetic needs of different markets. A modular production line is key – through independent molding, surface treatment, and assembly units, the manufacturer can quickly switch between insulation bottles, smart cups, outdoor pots,,s and other categories to meet the demand for small quantities and multiple varieties, and avoid lagging in capacity deployment.

4. Compliance & Quality Assurance

It is necessary to examine whether the factory has passed ISO 9001, BRCGS, and other international certifications and has market-specific compliance capabilities for the target market, and at the same time, establish a strict whole-process quality control system from raw material traceability to finished product testing to ensure product safety and stable performance.

5. Green Manufacturing Leads the Trend

Assess green metrics like recycled material ratios and clean energy usage, alongside digital capabilities (MES system coverage, order response speeds). Align with global sustainability and smart production trends to reduce environmental costs and improve efficiency.

Under the new situation, high-quality manufacturing partners should have the ability of “localized rapid response” and “global resource integration”, and become the strategic pivot for brands to expand the market rather than just the production side. How to choose resilient and innovative factories in the midst of fluctuations is becoming the core proposition of supply chain competitiveness.

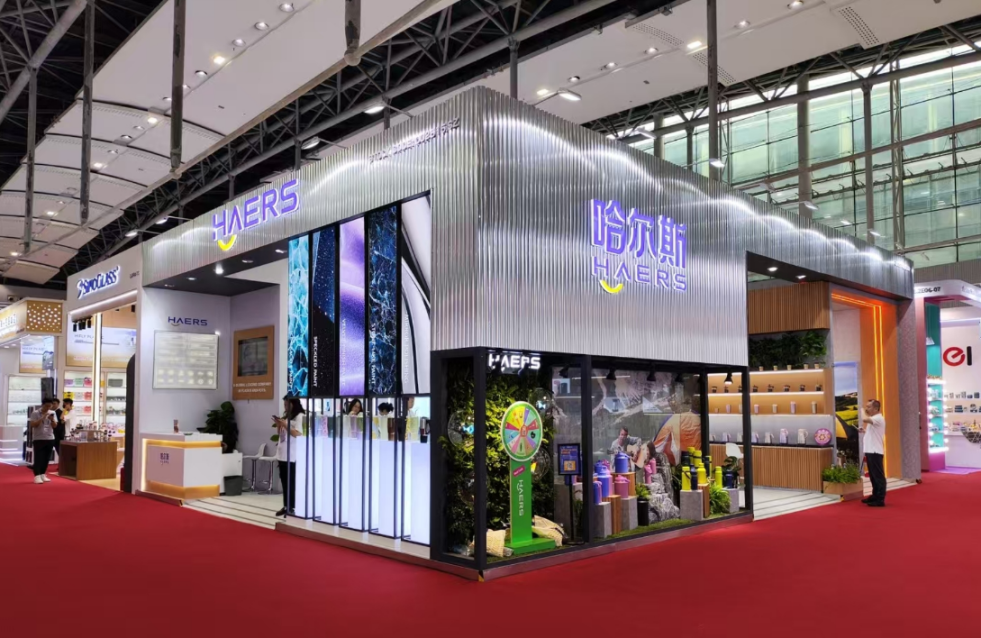

Core Strengths: From Technological Depth to Global Collaboration

As a leading enterprise in China’s drinkware industry, Haers has established a “Global Manufacturing + Local Expertise” framework, building a production and supply chain network spanning five continents. This provides international clients with intelligent manufacturing solutions that balance stability and innovation while offering critical guidance for selecting drinkware manufacturing partners in complex market environments.

1. Global Production Layout for Resilient Supply Chains

Haers has established five manufacturing and supply chain bases in Yongkang, Lin’an, and Anhui, as well as Thailand and Switzerland, with a total production area of 3 million square feet and an annual production capacity of more than 100 million units, covering the full range of products such as insulated bottles, smart cups, aluminum bottles and so on. By advancing automation, Haers has boosted production efficiency by 15% and reduced order lead times to 30 days.

The Thailand base, as the core hub in Southeast Asia, is equipped with intelligent production lines and full-process vertical integration capabilities, significantly shortening the regional delivery cycle. This decentralized production strategy effectively mitigates supply chain risks from localized disruptions under evolving global conditions, addresses regional logistics vulnerabilities, and enables rapid responses to diverse market demands with flexible capacity allocation.

2. Technological Innovation Setting Industry Standards

In order to cope with diversified market demands, Haers has built a product matrix of 300+ SKUs, covering outdoor sports, home office, smart health, and other scenarios. Through the modular production line design, enterprises can quickly switch the production of different categories such as insulated bottles, smart cups, children’s cups, etc., and support batch customization. Automated production realizes the significant advantages of “low cost, short delivery time, high quality and high efficiency”, reduces manual intervention, ensures product quality stability; improves production efficiency, shortens the manufacturing cycle; reduces labor and time costs, and enhances cost competitiveness.

Haers has a 500+ R&D team and has obtained a total of 695 patents, covering the fields of vacuum insulation, lightweight, and appearance technology. Haers’ mature lead-free welding technology eliminates the environmental pollution and harm caused by lead, while titanium cup innovations meet high-end demands for lightweight safety. In the field of intelligence, Haers has developed various kinds of smart cups, supporting real-time temperature display, drinking water records, tea-brewing assistance,e and other functions, becoming the industry’s leading smart cup products.

3. End-to-End Quality Control & Green Manufacturing

Haers strictly implements ISO 9001 and BRCGS double international certification system, and the products meet FDA, LFGB, and other food contact standards. Several quality inspection procedures are set up to realize traceability from raw materials entering the factory to finished products leaving the warehouse.

In quality inspection, Haers has built a multi-level, full-process rigorous inspection system. Starting from the entry of raw materials into the factory, each batch of materials has to pass a number of hurdles, such as performance testing; during the production process, online monitoring and manual sampling are combined to control key process parameters in real time; after the finished product comes off the line, it has to undergo dozens of testing programs, such as insulation efficiency measurement, sealing pressure test, and abrasion and scratch resistance test.

4. Green Manufacturing Practices

Haers integrates green concepts into all aspects of product development and design, raw material selection, production, transportation, use, and recycling. From the establishment of the GHG emission data system and the strict implementation of ISO 14064 standards; to the systematic treatment of waste gas and water, the use of solar panels to produce clean energy; to the first to use environmentally friendly stainless steel raw materials, environmentally friendly plastic particles and recycled packaging materials to strive to promote the realization of the goal of carbon neutrality, Haers has always been in the full range of low-carbon environmental protection and promotion of sustainable development.

Up to now, Haers base already has 2048 solar panels, which can produce 2.92 million kWh of clean energy, and has obtained carbon footprint certification and related certificates, which is the first product carbon footprint certificate in the stainless steel bottles category, and is another proof of Haers practicing the green and sustainable development path. This “Green Manufacturing” model not only reduces production costs but also meets the requirements of the global market for sustainable development.

Strategic Solutions: Supply Chain Management in Complex Environments

Against the background of the complex and changing global market environment, Haers has built up a highly resilient supply chain system with innovative management strategies and advanced technology applications to realize efficient operation and flexible response.

1. Localized Production Mitigates Risks

In the face of fluctuations in the international market, Haers actively promotes localized production, such as setting up a base in Thailand, deeply integrating local resources, taking advantage of geographic location to shorten the delivery cycle in the region, and improving the efficiency of the supply chain. This kind of layout not only adapts to the characteristics of different market demands but also reduces logistics costs and transportation risks. The Thailand base greatly improves the response speed of orders in Southeast Asia, provides customers with more timely service, effectively enhances the supply chain’s ability to withstand regional market fluctuations, avoids regional logistics bottlenecks, shortens the order delivery cycle, and improves efficiency compared with the traditional model.

2. Digitalization Enables Agile Operations

Haers has built a digital ecosystem covering PLM, SRM, MOM, ERP, WMS, and CRM systems. This interconnected framework improves cost efficiency, management effectiveness, and market responsiveness. Real-time monitoring and data analytics optimize resource allocation across production, procurement, and sales.

3. Streamlined Processes for Rapid Delivery

With the help ofthe OTD program, Haers shortens the order delivery cycle and achieves faster and higher goals. Optimizing the whole process of order receiving, resource guarantee, front-end and back-end production, warehousing, and shipping, ensures that the links are tightly connected, improves efficiency, reduces inventory, and improves customer satisfaction at the same time. This extremely fast delivery capability enables it to respond quickly to demand and seize the first opportunity in the complex market.

In today’s accelerated reconstruction of the global industrial chain, Haers has set a new benchmark for the drinkware industry. When choosing partners, brands should prioritize supply chain agility, technological innovation, and quality assurance. Collaborating with globally positioned, locally adaptive enterprises like Haers empowers businesses to navigate challenges and seize growth opportunities in the new consumer era.